On National Nanotechnology Day (10/9/2020), the U.S. Department of Energy’s (DOE) Advanced Manufacturing Office (AMO) is featuring images from beyond

Advanced Materials & Manufacturing Technologies Office

October 9, 2020On National Nanotechnology Day (10/9/2020), the U.S. Department of Energy’s (DOE) Advanced Manufacturing Office (AMO) is featuring images from beyond the visual range of the human eye to show how this tiny technology is shaping big manufacturing breakthroughs.

At the nanoscale (10-9 meter)—100,000 times smaller than the thickness of a piece of paper—everyday materials behave differently and exhibit unique characteristics, such as high strength, better conductivity, and increased chemical reactivity.

AMO’s “nanomanufacturing” portfolio focuses on harnessing these properties to dramatically reduce energy use and improve the performance of materials, structures, devices, and finished goods—supporting emerging technologies that bolster the competitiveness of U.S. manufacturers.

AMO’s work includes:

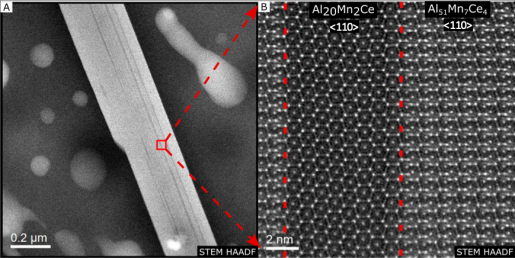

- Testing new materials with enhanced strength, toughness, or wear-resistance properties, such as particles that can improve the performance of energy-storage devices, catalysts that enable energy-efficient chemical manufacturing, alloys with higher conductivity and better performance under harsh conditions, and more.

- Developing new manufacturing tools, methods, and products, including additive manufacturing to create defect-free materials, and new ways to manufacture electronics on the nano and micro scale.

- Making nanotechnology more scalable and manufacturable through new processes, e.g., nanotechnologies that can operate in room-temperature environments.

The photo galleries below showcase the range of nanotechnology projects in AMO’s research and development (R&D) portfolio, as well as beautiful “nanoart,” demonstrating the incredible capability of modern, nanoscale imaging and manufacturing methods.

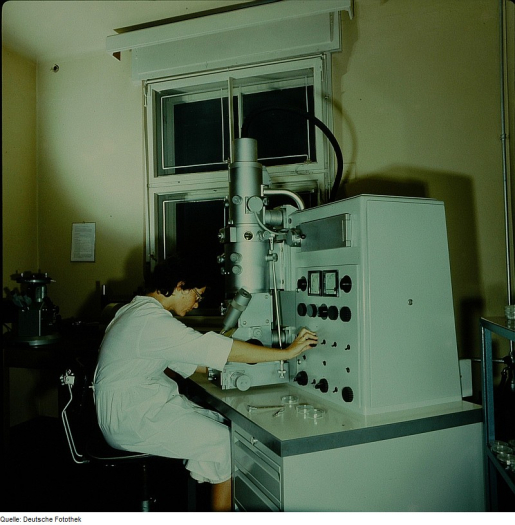

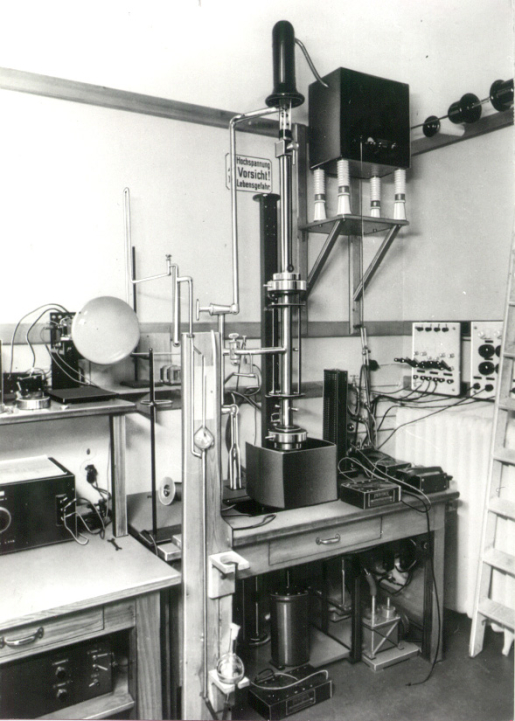

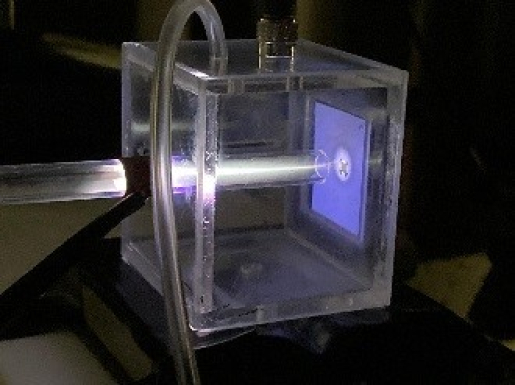

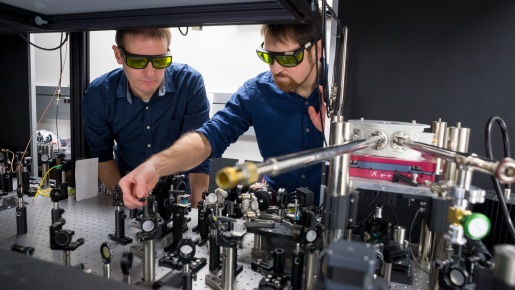

Nanoscale Tools

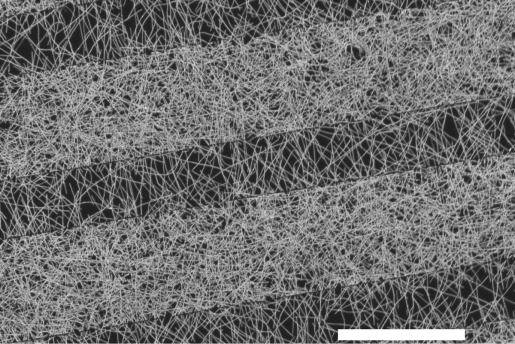

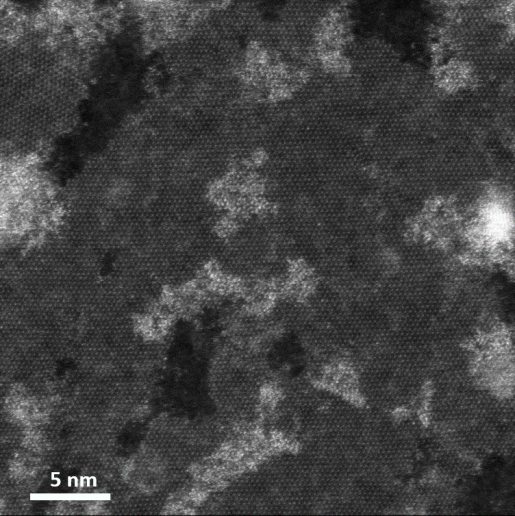

Capturing images at the nanoscale required scientific and engineering breakthroughs. Today, researchers have a range of tools that allow them to "visualize" and manipulate materials at a scale far beyond what human beings can see. These microscopes use electrons, photons, or other probes to create and gather data. With the help of advanced computing, these instruments then transform the signals into the images seen below.

For more information on seeing at the nanoscale, visit the National Nanotechnology Initiative’s website.

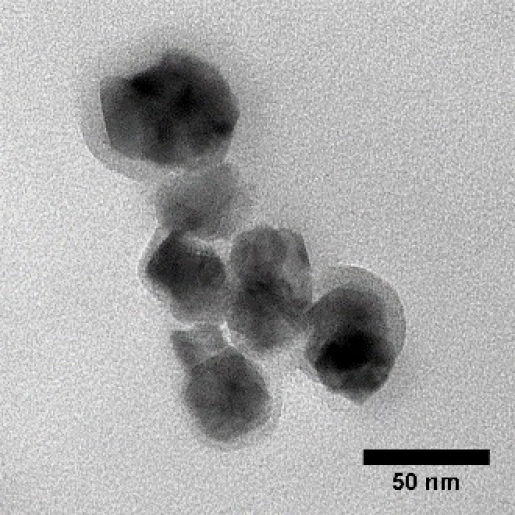

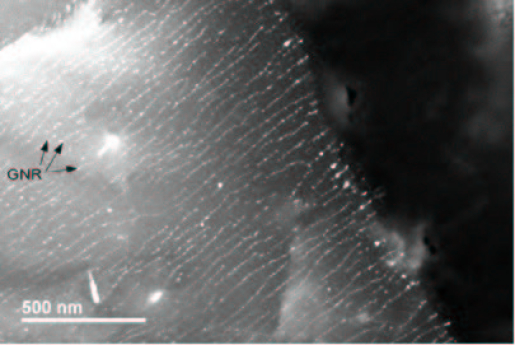

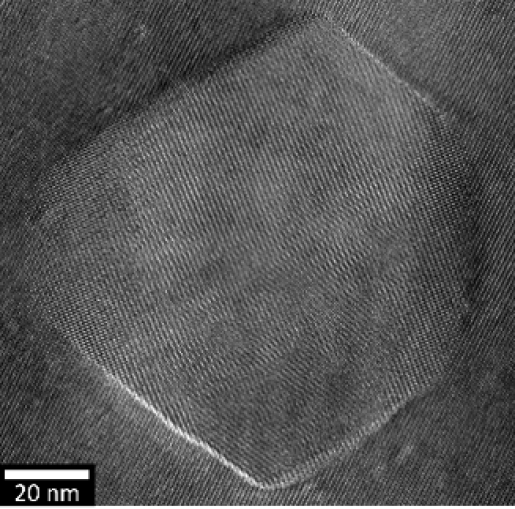

Energy Storage

As a part of the DOE-wide Energy Storage Grand Challenge, AMO aims to develop a strong, diverse domestic manufacturing base with integrated supply chains to support U.S. energy-storage leadership. In support of this goal, AMO is using nanotechnology to explore new materials that can address energy-storage material challenges—such as the need for robust, conductive, encapsulated particles that can withstand the volume and temperature-change requirements in thermal energy storage, as well as new materials that improve energy density and service lifetimes of electric energy-storage technologies, such as batteries and capacitors.

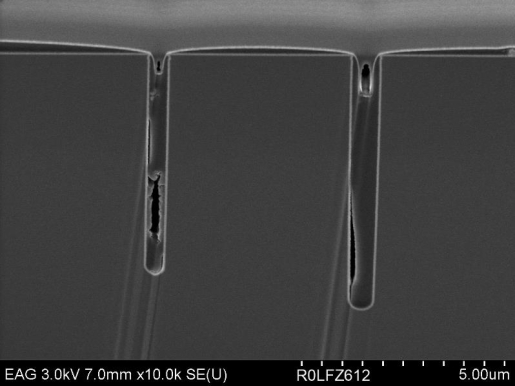

Novel Manufacturing Tools and Methods

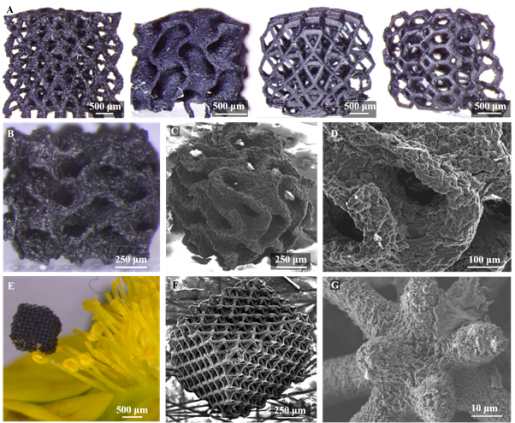

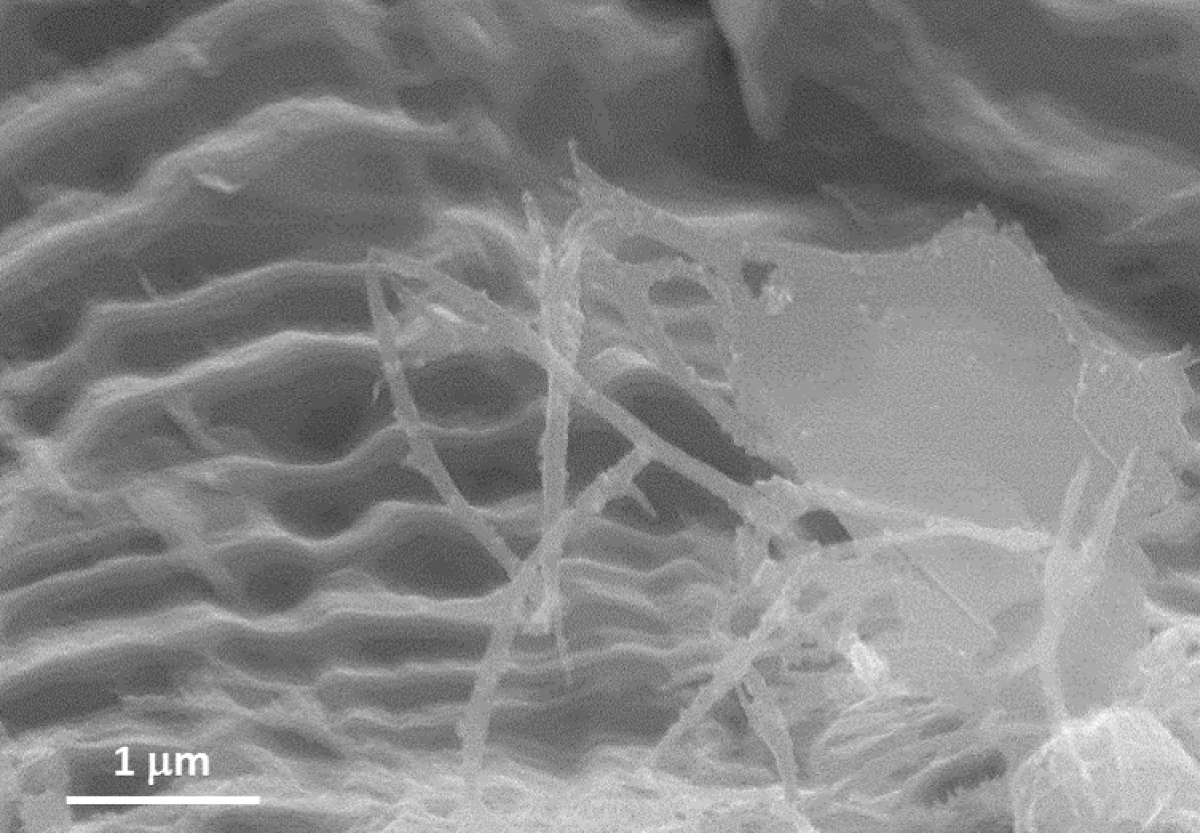

Additive manufacturing—also known as 3D printing—allows manufacturers to innovate quickly, design flexibly, reduce energy use, and use materials more efficiently. Additive-manufacturing processes can also be used to generate nanoscale features, such as nanoscale precipitates within solid-metal parts, that can be tailored to produce high-performance properties, such as high-strength, high-temperature fatigue life, or improved toughness.

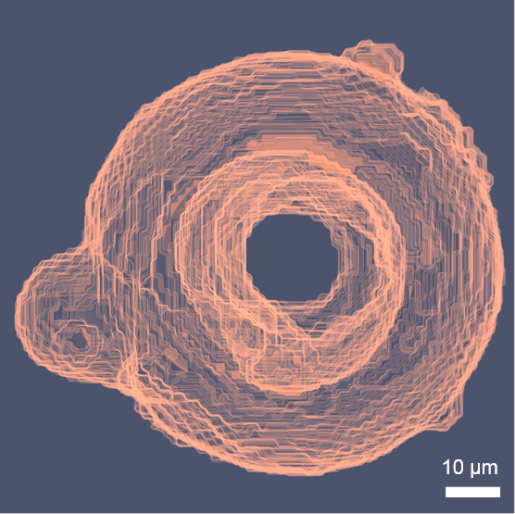

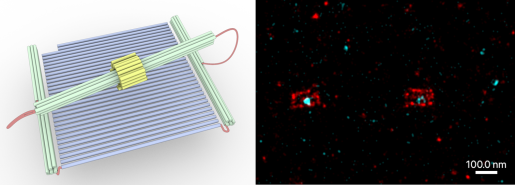

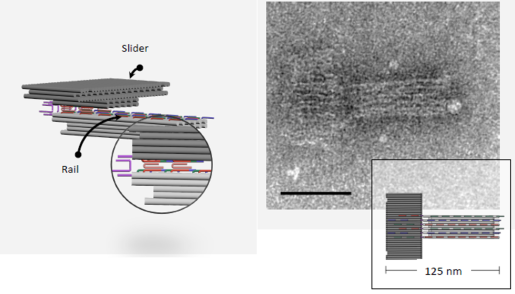

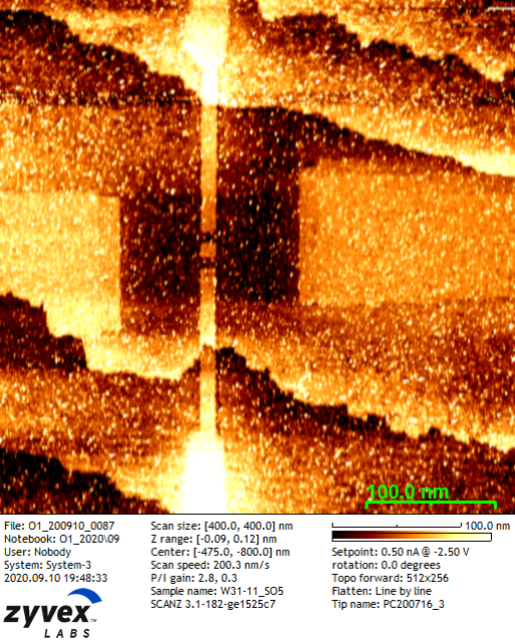

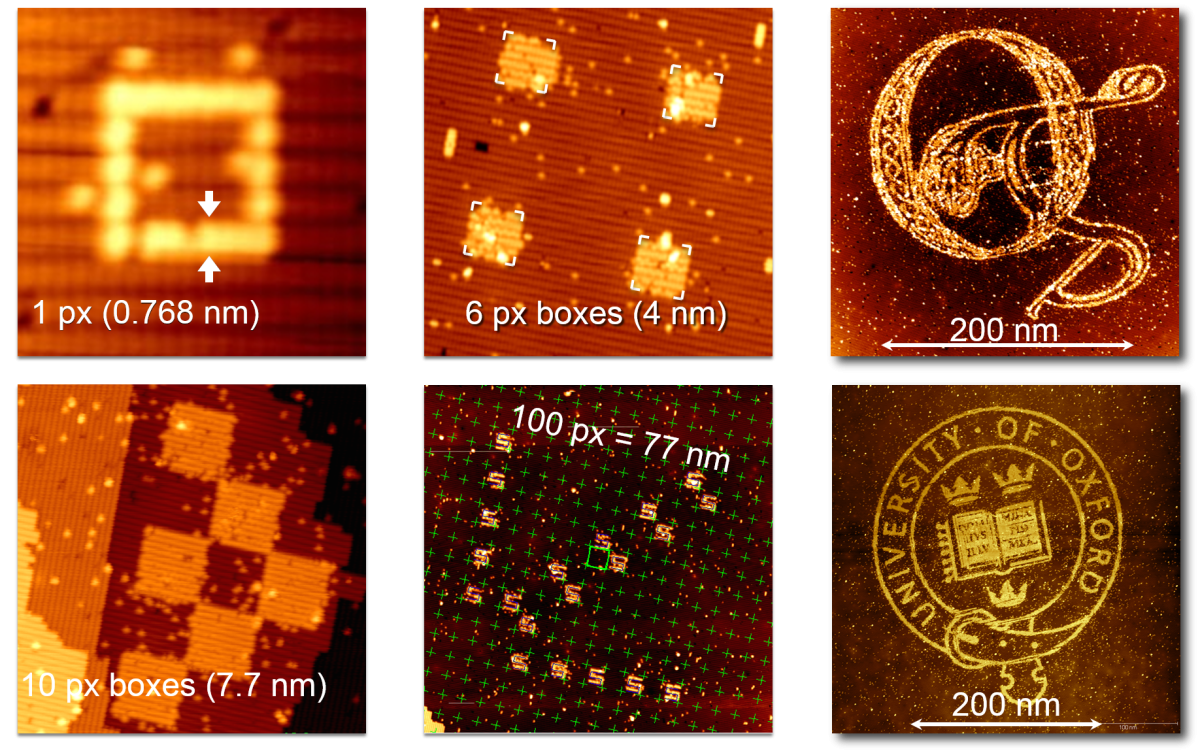

In addition to additive manufacturing, nanoresearchers are developing bio-inspired, “self-assembly” manufacturing methods, such as “DNA origami.” This method involves using DNA strands as construction materials that self-assemble by “folding,” like paper origami, into a wide variety of DNA-molecule-scale 2D and 3D shapes. This new technology could be used for a range of applications, including semiconductor-DNA hybrids for computing and data storage.

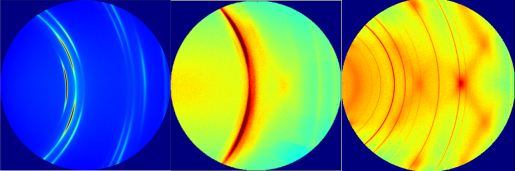

Water

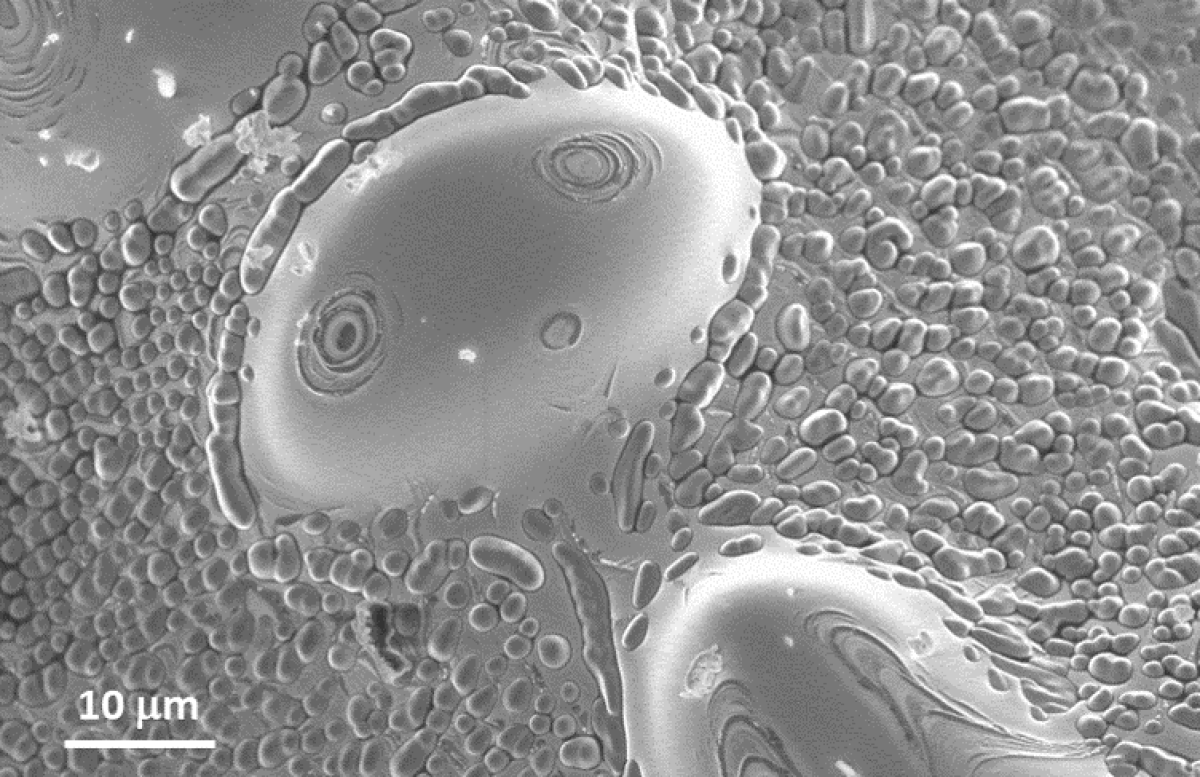

As a part of the Water Security Grand Challenge, AMO is pursuing transformational technology and innovation to meet the global need for safe and secure water. Part of this work includes creating fresh water from non-traditional water sources at pipe parity. Nanotechnology may be able to support new filtration methods to achieve this goal.

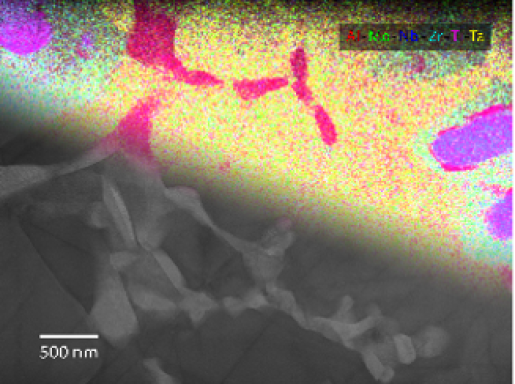

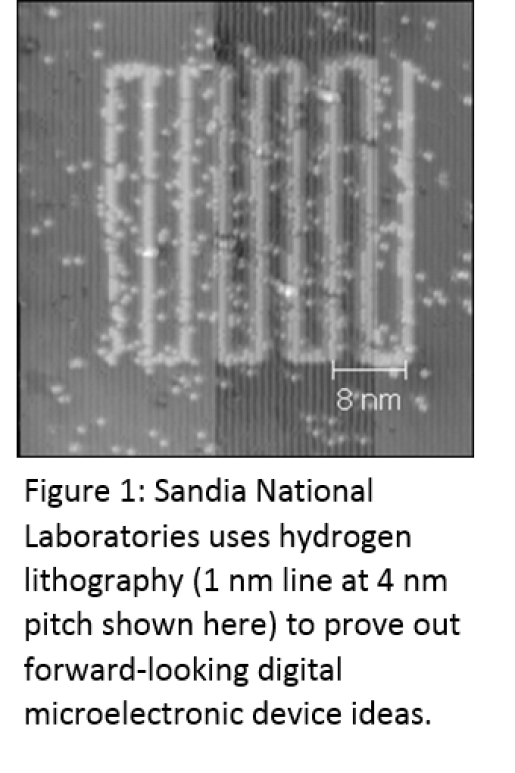

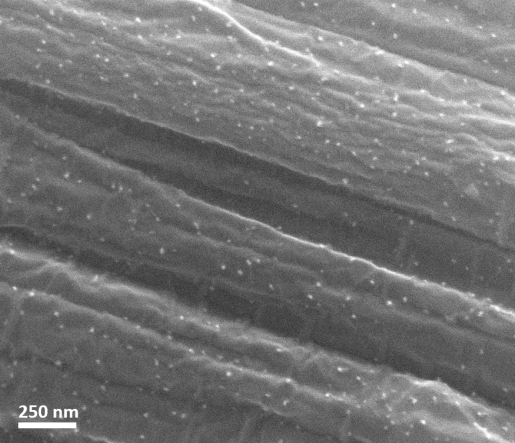

Microelectronics

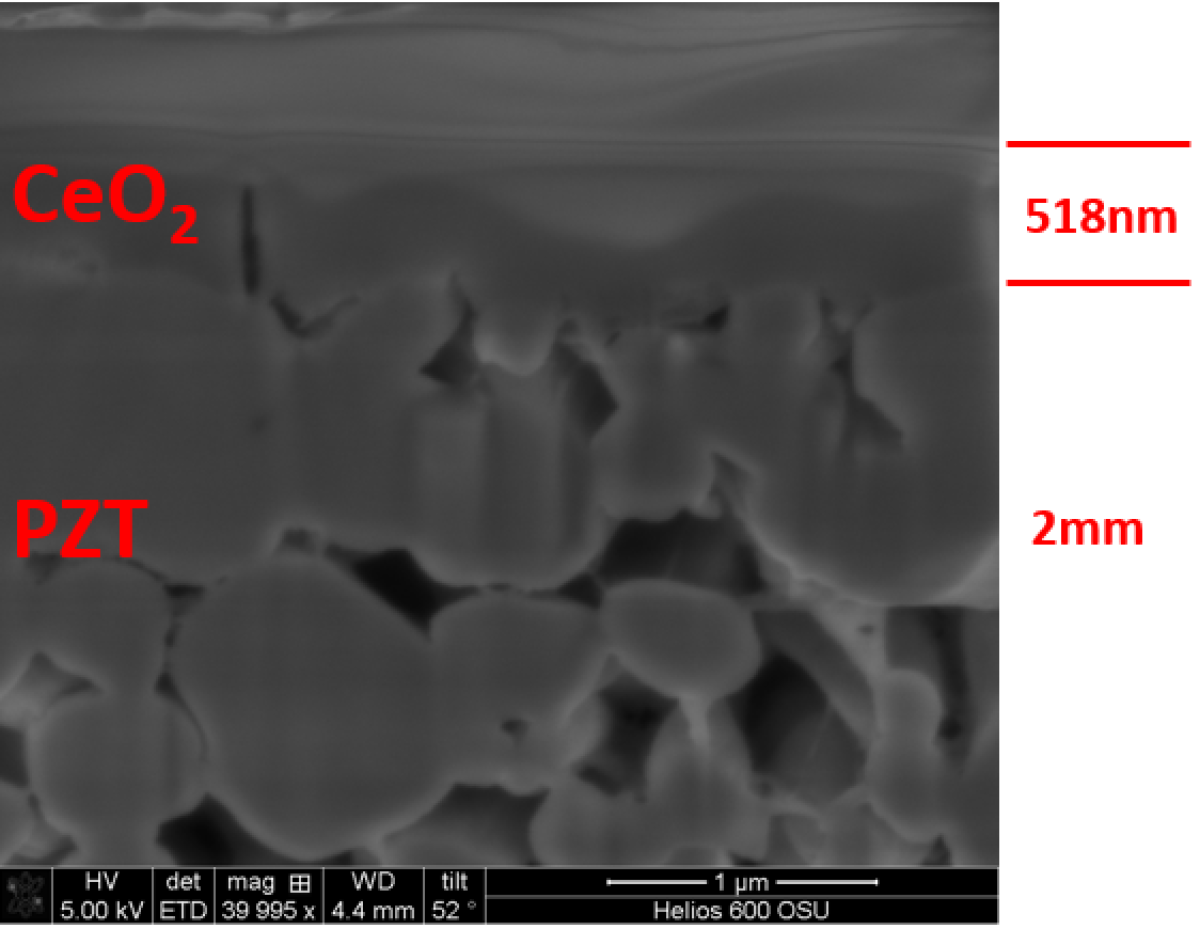

Microelectronics—electronic designs and components made at the tiniest scale—enable the development of high-performing, smaller transistors and capacitors. This research is vital for pursuing next-generation technologies to support the anticipated increase in the density of electronic devices.

In addition to building very small components, AMO’s microelectronics work includes new composite materials and manufacturing methods that offer improved properties, such as higher conductivity, compared to conventional technologies.

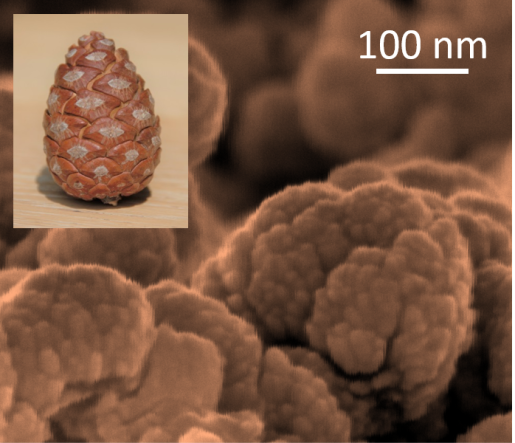

Chemical Manufacturing

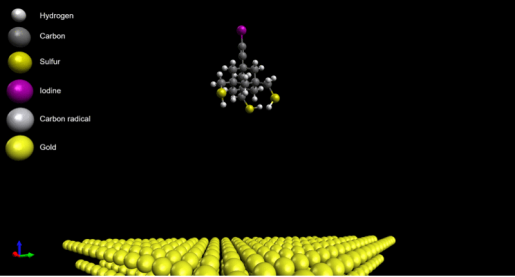

When applied to chemical manufacturing, nanotechnology offers the opportunity to develop new, atomically precise catalysts—materials that increase the rate of a chemical reaction—for specific processes that dramatically reduce energy intensity and improve material productivity for industry.

One way nanotechnology can improve the energy efficiency of chemical manufacturing is by offsetting the need to use high heat to manufacture chemicals. It can also optimize manufacturing processes to produce a desired chemical without byproducts, which consume energy and material while creating waste.

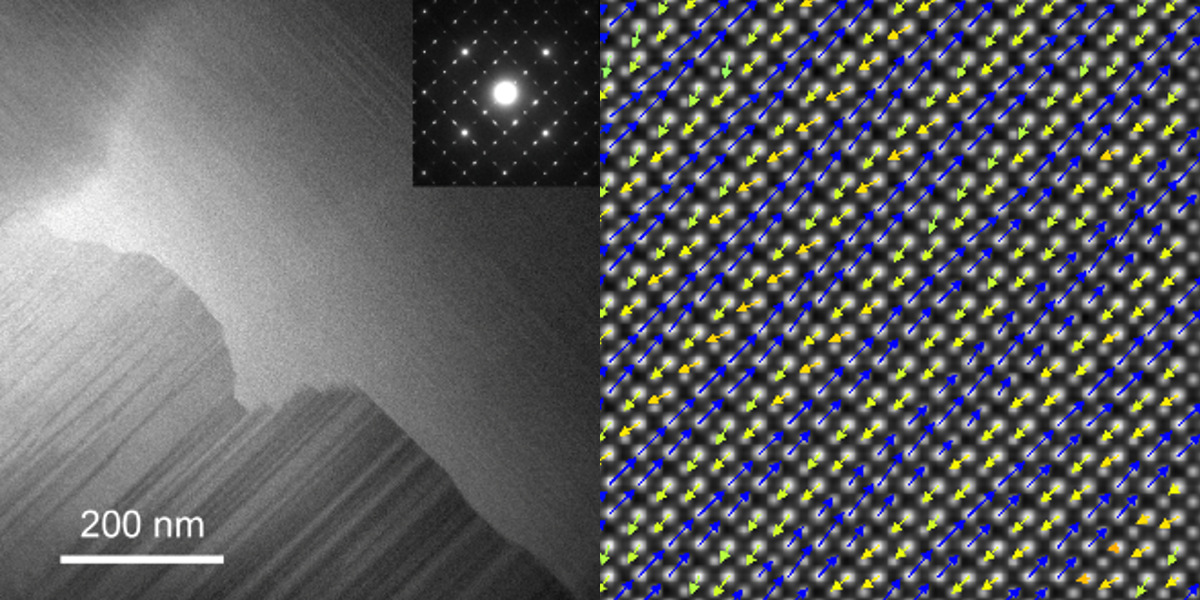

Nanoart

The ability to capture and create visually striking images on this very small scale demonstrates the incredible things that scientists and engineers are able to do with nanotechnology.

Happy National Nanotechnology Day! For more detailed reading, visit the AMO website for additional resources.

Join in the celebration on EERE’s Twitter, Facebook, and LinkedIn pages using #NationalNanoDay.

Visit the National Nanotechnology Initiative’s website to see how other individuals and organizations are highlighting National Nanotechnology Day.