Deploying distributed energy resources—technologies used to generate, store, and manage energy consumption for nearby energy customers—can help meet decarbonization and energy equity goals while increasing power system reliability and resilience. The Wind Energy Technologies Office’s (WETO) distributed wind research program is advancing wind energy technology as a distributed energy resource to contribute maximum societal, economic, and power system benefits.

What Is Distributed Wind?

Explore the potential use cases of distributed wind energy in your local community, including in residential, commercial, industrial, agricultural, and public facilities. Distributed wind energy has the potential to diversity local energy sources to help provide clean renewable energy in your community.

Click on the interactive animation or read a text version of the use cases.

View the full-screen version of the animation or read the text version.

Wind turbines used as a distributed energy resource—known as distributed wind—are connected at the distribution level of an electricity delivery system (or in off-grid applications) to serve on-site energy demand or support operation of local electricity distribution networks.

Distributed wind installations can range from a less-than-1-kilowatt off-grid wind turbine powering telecommunications equipment, to a 15-kilowatt wind turbine at a home or small farm or a 100-kilowatt wind turbine at a university campus or industrial facility. Distributed wind can also be several multimegawatt wind turbines owned by a local community or the local electricity distribution utility.

Individuals, businesses, and communities install distributed wind energy to offset retail power costs or secure long-term power cost certainty, support grid operations and local loads, enhance resilience with backup power, and electrify remote properties and infrastructure not connected to a centralized grid.

Distributed Wind Research Program Goals

WETO’s research and development, or R&D, efforts aim to maximize confidence in turbine performance and safety (by increasing the number of small and medium wind turbine designs tested to national performance and safety standards) and to improve distributed wind energy’s cost effectiveness (by reducing its levelized cost of energy [LCOE]). Achieving these goals can lead to increased consumer adoption and deployment.

WETO’s Multi-Year Program Plan outlines the Office’s research priorities and plans through the year 2025, including those for distributed wind.

Current Research Highlights

WETO supports a portfolio of interrelated R&D efforts with the U.S. Department of Energy’s (DOE) national laboratories as well as academia and industry stakeholders. In addition, WETO invests in leading edge, world-class test facilities and research capabilities at the national laboratories.

WETO convened laboratory and industry stakeholders conducting WETO-funded projects to promote collaboration across the program. The Distributed Wind Research Program Workshop Report provides reference material for both current and potential future WETO-funded distributed wind research projects.

WETO’s distributed wind research program focuses on six primary areas to advance wind energy technology as a distributed energy resource:

Data, Analysis, and Modeling

While distributed wind stakeholders may often focus on their individual companies, research, or product development, WETO approaches distributed wind analysis and modeling holistically, looking at transformative solutions for the entire industry. WETO develops and disseminates independent, fact-based distributed wind data, analysis, and modeling tools to educate stakeholders, support the identification and prioritization of WETO’s research and development efforts, and to address research needs that cannot be met at the individual level.

WETO’s annual Distributed Wind Market Report provides stakeholders with statistics and analysis of the distributed wind market, along with insight into its trends and characteristics. The report analyzes distributed wind projects of all sizes. It was difficult to make year-to-year comparisons, measure growth, and identify trends in the industry before WETO initiated the report series. The annual Distributed Wind Market Report details the U.S. small and medium wind markets, as well as multimegawatt wind deployments in distributed applications.

Assessing the Future of Distributed Wind: Opportunities for Behind-the-Meter Projects

WETO’s market potential research identifies the best locations and sectors for distributed wind deployment to inform the distributed wind industry’s approach to market growth. In 2016, WETO released Assessing the Future of Distributed Wind: Opportunities for Behind-the-Meter Projects, a first-of-its-kind analysis that characterizes the future opportunity for behind-the-meter distributed wind—that is, distributed wind behind a customer’s utility meter that offsets all or some of the on-site energy needs. The assessment suggests that behind-the-meter distributed wind could play a substantial role in the nation’s electricity future. Achieving this future will require technology cost reductions, improved power performance, and new business models that can access low-cost capital, support turnkey solutions, and drive industry-wide efficiencies.

As an update to the 2016 analysis, the Distributed Wind Futures Study explores the role of distributed wind in a carbon-pollution-free power sector by 2035. The study builds on the 2016 analysis by using higher-resolution data and new modeling techniques to highlight geographic trends in market potential, compares the cost and performance of front-of-the-meter and behind-the-meter installations, and examines the trade-offs consumers face when deciding between distributed wind and solar photovoltaics. The results are viewed through the lenses of grid decarbonization, environmental justice, and opportunities for rural and agricultural communities.

Distributed Wind Energy Futures Study

Released by WETO in 2022, the Distributed Wind Energy Futures Study found the United States currently has the potential to profitably deploy nearly 1,400 gigawatts (GW) of distributed wind energy capacity. This amount equates to more than half of the nation’s current annual electricity consumption and is enough to provide millions of American households with clean power. With favorable regulatory and policy direction, distributed wind energy could provide even more profitable power generation potential in the coming decades.

Distributed wind technology can supply rural homes, businesses, and communities with local clean energy resources that foster an energy transition and support the nation’s low-carbon-emissions goals.

- Cost of Wind Energy Review

- Technology Innovation Pathways for Distributed Wind Balance-of-System Cost Reduction

- Open-source dWind model code used for Futures Study analysis.

Deployment Acceleration

For distributed wind to realize its potential contribution to national decarbonization and environmental justice objectives, consumers and stakeholders need support to evaluate, develop, and operate distributed wind systems and hybrid systems (e.g., wind-, solar-, and storage-powered microgrids). Many U.S. regions that have quality wind resources, high retail electricity rates, and population densities acceptable for all scales of distributed wind deployment are rural. To date, however, rural electric utilities and the communities they serve have experienced limited distributed wind deployment due to a lack of resources and tools to support decision making.

The National Distributed Wind Network and complementary Distributed Wind Resource Hub offer extensive informational resources about distributed wind to help homeowners, farmers, utilities, communities, and business owners navigate their decision making around distributed wind—with the goal of increasing the successful deployment of distributed wind turbines across the country. These resources support the Rural and Agricultural Income & Savings from Renewable Energy (RAISE) Initiative, with an initial goal of helping 400 individual farmers deploy smaller-scale wind projects.

WETO launched its Wind Innovations for Rural Economic Development (WIRED) initiative with a workshop to learn about the unique needs, challenges, and experiences rural electric cooperatives and communities have with distributed wind. WIRED supports the creation of decision support tools and other resources that rural electric utilities and communities can use to develop distributed wind projects. WETO also partners with DOE’s Energy Transitions Initiative to advance self-reliant islands and remote isolated communities by developing resilient, carbon-free energy systems.

The National Distributed Wind Network is an inclusive convening platform for distributed wind stakeholders from around the country to coordinate, collaborate, and learn from peers and leading experts on issues that matter to them.

The Distributed Wind Resource Hub, a primary feature of the National Distributed Wind Network, includes general information about distributed wind energy, project funding and technical assistance opportunities, case studies of successful distributed wind energy projects, and models, tools, and toolkits to help users assess their location for distributed wind energy.

As part of the WIRED initiative and led by National Rural Electric Cooperative Association Research, the goal of the Rural Area Distributed Wind Integration Network Development (RADWIND) project is to understand, address, and reduce the technical risks and market barriers to distributed wind adoption by rural utilities. This is being done by identifying solutions (provided in a toolkit), developing sharable resources (such as a financing, incentives, and business models report), and demonstrating technology by and with rural communities (through numerous case studies).

Supported by the WIRED initiative, Bergey WindPower, in partnership with Oklahoma Electric Cooperative, Intergrid, and Juhl Energy, is developing a distributed energy resource sales business model that would enable rural electric utilities to offer a distributed energy resource solution directly to customers. In this business model concept, a rural electric utility would finance and sell a hybrid distributed wind-solar-storage microgrid system to its utility customers. The customer would benefit from federal tax credits, utility bill savings, and enhanced resilience from backup power. The rural electric utility would benefit from reduced peak electricity demand, grid support capabilities, and potential deferral of distribution system upgrades.

Remote, island, and islanded communities are shifting to cleaner and more resilient energy systems. The Energy Transitions Initiative Partnership Project supports community-driven energy transition planning with technical assistance. As part of the partner network, WETO provides funding to national laboratories and regional partners for the provision of distributed-wind-specific technical assistance.

Systems Integration

Controls and power electronics hardware to integrate wind energy technologies with other distributed energy resources and into distribution grids, microgrids, and hybrid systems are not well developed or standardized. In addition, the tools used to inform decision making around grid system planning and operations often do not fully characterize distributed wind compared to other distributed energy resources. As contributions from variable renewable resources have increased on microgrids and distribution grids, the need for wind to integrate in a seamless plug-and-play manner with other distributed energy technologies is critical for consumer adoption.

WETO’s research in distributed wind systems integration seeks to develop and validate wind technology as a plug-and-play resource with solar, storage, and other distributed energy resources to support grid system reliability and enhanced power system resilience. Through the WIRED initiative, WETO is supporting research to optimize the integration and operation of distributed wind with other distributed energy resources. The goal is to strengthen rural electricity distribution networks and provide additional grid support services. WETO is also supporting foundational research in advance turbine controls, valuation of grid support services, and approaches for enhancing both resilience and cybersecurity.

WETO hosted the Wind Systems Integration Workshop as a collaboration between WETO’s Renewable Systems Integration and Distributed Wind Research programs. The Wind Systems Integration Workshop Report summarizes the near-term research challenges and opportunities for the priority topics of grid services, modeling and decision-support tools, power electronics, and energy equity.

With increased levels of distributed energy resource deployment, rural electric utilities need new approaches to address potential integration and operational challenges. The Iowa State University project, supported by the WIRED initiative, is designing optimization models and advanced control schemes to enable rural utilities to leverage distributed wind in coordination with storage and other synergistic distributed energy resources. Doing so will allow utilities to provide clean emergency power after outages, reduce peak electricity demand, and mitigate operational vulnerability in weak rural distribution grids. Potential benefits to rural utilities include cost savings, enhanced system reliability, and increased resilience.

Rural electric utilities need better tools to evaluate, plan, and operate co-located distributed wind and battery storage systems. The Wind Intelligently Integrated into Rural Energy Systems (WIIRES) project, which is part of the WIRED initiative and led by the Electric Power Research Institute in partnership with the National Rural Electric Cooperative Association and General Electric, is helping to address this need. WIIRES is identifying, improving, and publishing modeling, planning, and operation methods for deploying and operating distributed wind with battery storage. The WIIRES project will provide better tools for rural power system operators and electric utilities to manage increased amounts of distributed wind plus battery storage on rural grids while maintaining cost, power quality, and reliability.

For individuals, businesses, and communities building resilient electric infrastructure, wind energy can provide an affordable and compatible distributed energy resource option that enhances the operation of distribution networks, microgrids, and hybrid systems.

The Microgrids, Infrastructure Resilience, and Advanced Controls Launchpad (MIRACL) project aims to ease the integration of distributed wind into microgrids, isolated grids, distribution grids, and hybrid power plants. The project achieves this by improving valuation and power system modeling techniques, developing advanced turbine control capabilities, and providing greater resilience. MIRACL research publications can be found on webpages hosted by DOE’s National Renewable Energy Laboratory, Pacific Northwest National Laboratory, and Idaho National Laboratory.

Small and Medium Wind Turbine Technology R&D

Small wind turbine technology is commonly defined as turbines with rated capacity of less than or equal to 100 kilowatts. Medium wind turbine technology is commonly defined as turbines with rated capacity of greater than 100 kilowatts and less than or equal to 1 megawatt. Because small and medium wind turbine technologies deployed today are exclusively used in distributed applications, they are the primary wind turbine technology R&D focus areas in the distributed wind research program.

Cost reduction and power performance improvements are critical for small and medium wind turbine technologies to remain an economically viable distributed energy resource option. In addition, turbine testing for certification to national performance and safety standards is an essential step to qualify new technology for commercialization and incentive programs. However, testing turbines to rigorous standards is time intensive and can hinder a small company’s ability to take its product to the market. Consequently, WETO’s research and support aims to address this potential market barrier and advance small and medium wind turbine technology as cost competitive, compatible, and reliable distributed energy resource options.

The distributed wind industry requires innovation to advance technology, reduce costs, and access new markets, but many companies in the industry do not have the resources to develop, certify, and commercialize next-generation technology. WETO launched the Competitiveness Improvement Project (CIP) to address this gap and maintain U.S. leadership in the domestic and international distributed wind turbine sector.

CIP, which is funded by DOE and administered by the National Renewable Energy Laboratory, awards cost-shared subcontracts via a competitive process to manufacturers of small and medium wind turbines.

CIP is aligned with the goals of WETO to make small and medium distributed wind technology cost competitive with other distributed energy resources, as measured through levelized cost of energy reduction, and to increase the number of small and medium wind turbine designs tested to national performance and safety standards, as measured through the number of tested designs.

The technical objectives of CIP are to increase energy production and grid support capabilities, develop advanced manufacturing processes to reduce hardware costs, conduct turbine and component testing to national standards to certify performance and safety, and to accelerate commercialization and deployment of next-generation technologies.

Visit the CIP webpage for more information.

Historically, the small and medium wind turbine industries have seen many new products enter the U.S. market without a framework to verify manufacturer claims about turbine performance, reliability, noise, and safety. In response, WETO established a national framework for small and medium wind turbine testing to national performance and safety standards, and helped establish the Small Wind Certification Council, now the International Code Council-Small Wind Certification Council. WETO also continues to support the development of technical standards that can be used voluntarily to test small wind turbines to performance and safety criteria.

Certifying a small or medium wind turbine model to standards allows manufacturers to demonstrate that the turbine model meets performance, durability, and quality requirements, and establishes common performance metrics to enable comparisons. Certifications issued by independent, accredited third-party certification bodies allow wind turbine manufacturers to demonstrate compliance with regulatory and incentive program requirements. Certified ratings also allow purchasers to directly compare products, and give funding agencies and utilities greater confidence that small and medium turbines installed with public assistance comply with applicable standards.

When conflicts and natural disasters unfold around the world and military or civil humanitarian response is needed, quick access to on-location energy is critical to ensuring a successful mission or crisis response. The Defense & Disaster Deployable Turbine project is evaluating the market potential for rapidly deployable small and medium wind energy technologies, developing wind turbine design guidelines for operational applications, and assessing commercially available wind technologies against operational design requirements to help identify technology gaps and R&D opportunities.

Download the project fact sheet for more information.

The Interstate Renewable Energy Council maintains a list of certified small wind turbines.

The International Code Council-Small Wind Certification Council maintains a list of testing organizations that provide testing services for small and or medium wind turbines seeking certification in North America.

Learn more about small wind with WINDExchange’s Small Wind Guidebook.

Resource Assessment

Accurately and cost-effectively predicting the power performance of distributed wind installations, particularly those using small wind turbine technology, is a technical challenge. Consequently, consumers and policymakers have less confidence in small-scale distributed wind and small wind projects tend to have high project development costs. The cost and long timeframes of current measurement-based wind resource assessments used by large wind farm developers are not suitable for small wind installers and developers. This often forces small-wind installers and developers to use rule-of-thumb methods and simplified model-based approaches instead, leading to uncertainty in the estimates and a tendency to overestimate production.

The resource assessment focus area of the distributed wind research program aims to provide data, modeling tools, and information to help customers and stakeholders evaluate the quality of the wind resource in their region, territory, and backyard. In doing so, WETO is striving to reduce the cost and time required to develop a wind resource estimate while increasing the accuracy.

The measurement-based wind resource assessments employed by the utility-scale wind industry are costly and require a long data collection time period, leading distributed wind developers to use simplified desktop approaches and rules of thumb, which can introduce error. The Tools Assessing Performance (TAP) project aims to reduce the time, cost, and uncertainty in desktop preconstruction project performance estimates—thereby improving stakeholder confidence and the representation of distributed wind in decision-support tools for system planning, design, and operation.

The TAP project team has created wind resource data and add-on features that are available via an application programming interface (API).

Visit the TAP project webpage for more information.

WETO’s WINDExchange provides educational materials to help communities weigh the benefits and impacts of wind energy, including Wind Resource Maps. These static maps illustrate multiyear average wind speeds at various heights for the United States. They provide a useful preliminary tool for understanding if average annual wind speeds in an area could be conducive to wind development.

Learn more about the maps with the Understanding Wind Resource Maps video.

Stakeholder Engagement

WETO has the ability to convene domestic and international stakeholders to address topics critical to advancing wind energy solutions. Ongoing strategic engagement allows WETO to understand industry needs, research needs, and how research projects can best be tailored to maximize the impact of federal (taxpayer) investment. As a result, WETO is involved in a variety of strategic and technical stakeholder engagement activities to accelerate the development, deployment, and integration of distributed wind.

WETO participates in the International Energy Agency Wind Technical Collaboration Programme and provides leadership for Task 41: Enabling Wind to Contribute to a Distributed Energy Future.

Task 41 is an international group of researchers dedicated to advancing wind technology as a cost-effective and reliable distributed energy resource. The task’s objectives are to coordinate international distributed wind energy research, facilitate collaboration on priority research topics, and increase the visibility of wind energy technology as a distributed energy resource. Task 41 research results are available on the International Energy Agency website.

Design standards are an important tool for communicating minimum design and testing requirements to product developers, and for communicating accredited product performance and safety information to consumers. WETO collaborates with stakeholders, such as the American Clean Power Association and the International Energy Agency Wind Technical Collaboration Programme, to develop technical standards that can be used voluntarily to test small and medium wind turbines to performance and safety criteria. WETO has hosted multiple forums to provide input on national and international standards development. The objectives of WETO’s standards development work are to ensure the rigor of the requirements without imposing unnecessary cost and time to comply.

Distributed Wind News

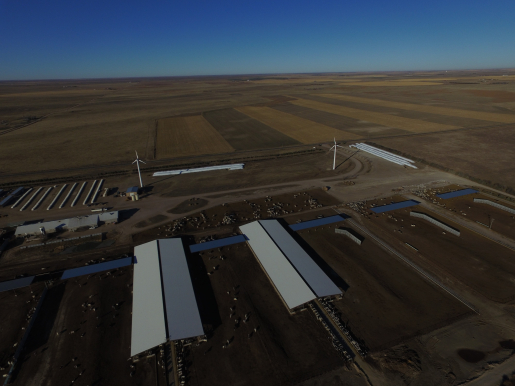

Distributed Wind Photo Galleries and Case Studies

More distributed wind photos are available in the NREL Image Gallery and the Pacific Northwest National Laboratory Distributed Wind Photo Gallery.

Case studies developed as part of the Distributed Wind Installers Collaborative are available at this webpage.

Case studies from the RADWIND project are available on the project webpage.

Featured Research Publications

Stay informed by receiving the latest wind energy research and development activities, news, events, and updates.