Molten salt reactors are nothing new.

They’ve been around since the 1960s and date back to the days of the Molten Salt Reactor Experiment at Oak Ridge National Laboratory.

Now, almost 60 years later, several companies are starting to develop molten salt reactors as energy systems of the future—including TerraPower, backed by Bill Gates.

Southern Company, a leading energy company in the United States, is partnering with TerraPower to develop a molten chloride fast reactor (MCFR) that uses liquid salts as both a coolant and fuel.

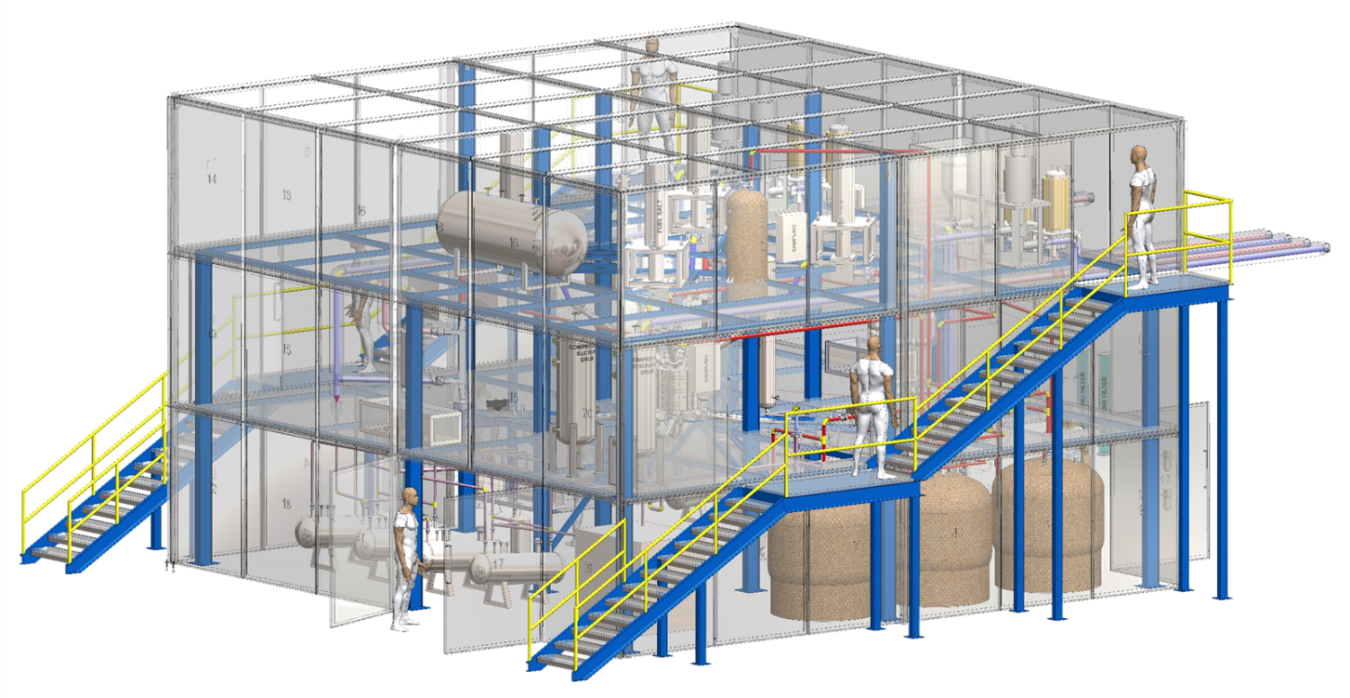

The U.S. Department of Energy (DOE) already invested more than $45 million in cost-shared funds for the project to further identify and test materials used in the reactor and will receive more than $136 million through DOE's Advanced Reactor Demonstration Program to help lower the risk of developing and building the Molten Chloride Reactor Experiment (MCRE).

How It Works

The MCFR will be optimized to operate as a commercial reactor that can produce up to 1,200 megawatts of electricity, with a lower-output demonstration reactor proving smaller-scale potential.

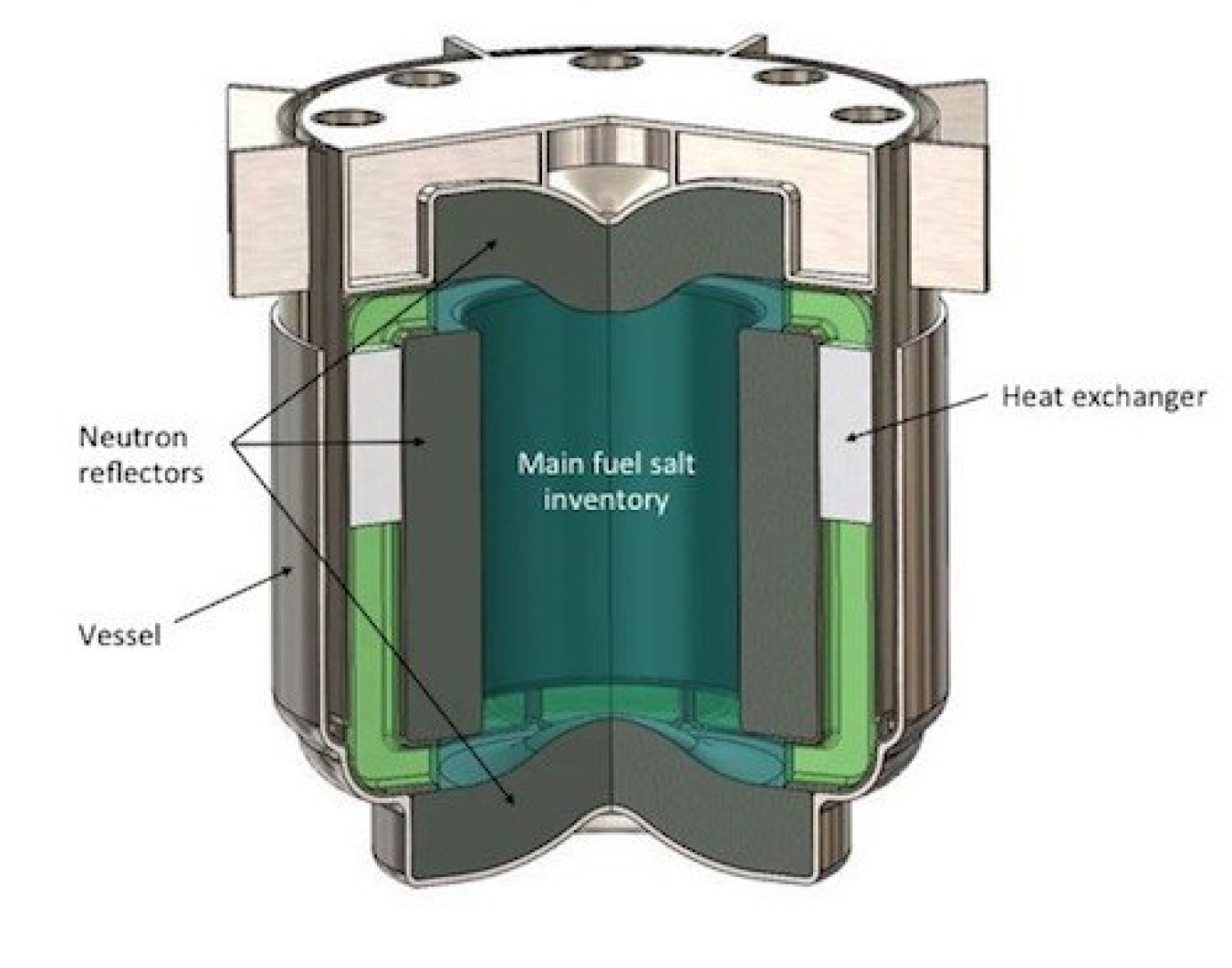

The design uses liquid chloride salts as the coolant and fuel that flows through the reactor core—allowing the fission to directly heat the salts. The mixture is then circulated through a heat exchanger to a coolant chloride salt loop that can be used for process heat, thermal storage or electricity generation.

Because the reactor operates at a high temperature, the process is more efficient at producing electricity than light water reactors. The reactor would also produce less waste and could even consume waste from other reactors.

MCFR Benefits

MCFRs can enable the transition to a flexible, robust and low-carbon energy system..

It is a major departure in terms of simplicity, fuel cycle and proliferation characteristics relative to other more-complex nuclear reactor concepts and offers significant safety, performance and economic benefits.

The MCFR has what the industry calls a “walk-away-safe” design that would shut down the reactor without any need for electric pumps to prevent fuel damage. If there is a loss of coolant flow, the fuel salt would expand through the reactor core to passively halt the process and naturally circulate to remove decay heat.

Other benefits include:

- No fuel assemblies to fabricate, replace or store

- Online refueling for continuous operation to increase fuel utilization and availability

- Ability to use multiple fuels for operation including depleted and natural uranium, or even spent fuel

- Enrichment only needed at startup

- Ability to load follow and support other energy sources on the grid.

What’s Next?