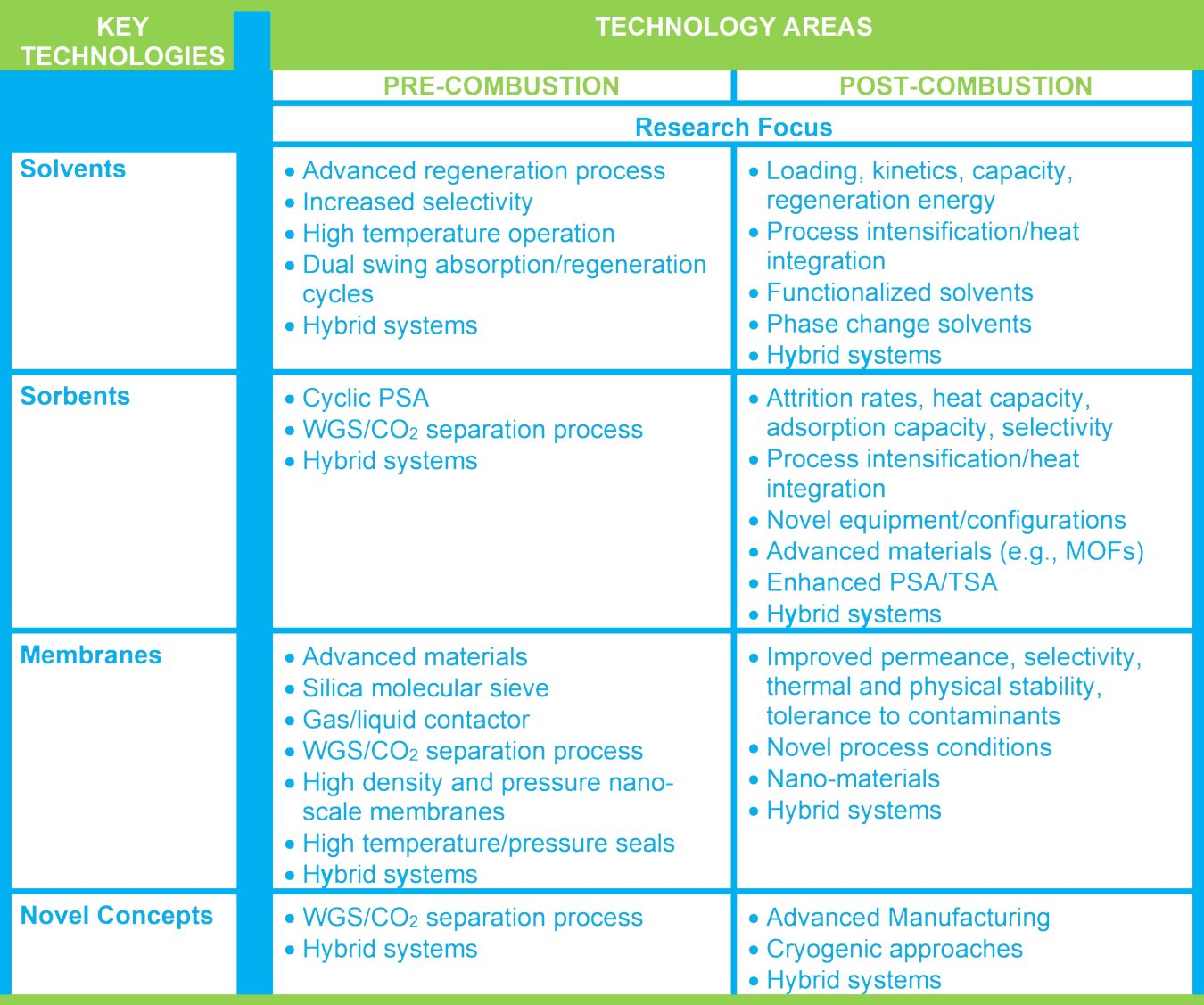

Carbon capture technologies represent the integration of a series of steps and processes, as illustrated below. Advancements in multiple components of a capture system are needed to improve cost and performance in order to approach Program targets.

The major components of the cost of current CO2 capture technologies are:

- Operating costs related to:

- Thermal energy requirements

- Electricity requirements for compression

- Materials consumption, such as solvents, sorbents and other chemicals

- Maintenance

- Capital costs related to:

- Equipment – particularly the size of the equipment - and related materials

- Integration for retrofits

Approaches that can be used to help drive improvements in cost and performance include the following:

- Improving Thermodynamics – reducing energetic requirements through lower regeneration energy requirements, lower pressure drops, lower required temperatures, improved capacity, process optimization

- Improving Kinetics – developing faster, more selective chemical/physical separation pathways that allow for the use of smaller, lower-cost, more efficient reactors

- Reducing Capital Cost – reducing total required equipment and costs through advanced manufacturing, process intensification, integration, and optimization

- Improving Durability – developing capture media (solvents, sorbents, and membranes) with rugged long-term performance and slow degradation rates

- Improving Scalability – providing economic viability at all relevant process scales

Techno-economic analyses (TEA) represent a key tool that the Carbon Capture Program uses to evaluate projects and technologies against cost and performance targets. All projects within the portfolio are required to prepare TEAs following standardized procedures. This ensures that all projects are evaluated using a consistent basis. In addition, sensitivity analyses that are often conducted in conjunction with TEAs can enhance the understanding of technology developers regarding the most fruitful avenues of cost reduction in their R&D efforts.

While TEAs can provide insight on cost and benefit tradeoffs, they cannot rigorously optimize the operation or configuration of a carbon capture system. To complement the TEA efforts, the Carbon Capture Program also funds an effort to develop and apply a tool set embodying a variety of advanced process simulation capabilities called the Carbon Capture Simulation for Industry Impact (CCSI2). CCSI2 develops and validates a hierarchy of fundamental material models through process level simulations that are used to optimize the configuration and operation of carbon capture systems to maximize their potential for cost effective CO2 mitigation. CCSI2 leverages experimental and pilot data in the development and validation of these models, while at the same time providing perspective on how uncertainty due to lack of sufficient data impact our ability to predict performance.

Much of the progress made in the development of 2nd-generation technologies resulted from improvements in thermodynamic performance. A significant challenge in meeting Program targets for Transformational technologies is driving down capital costs. This is being addressed through efforts noted below: