In 2014, NETL research led to 17 patents from the U.S. Patent and Trademark Office.

Each year, researchers at the U.S. Department of Energy’s National Energy Technology Laboratory (NETL) push the limits of innovation and are rewarded for their unique technological advancements by being issued U.S. patents. NETL researchers received 17 patents in 2014 for technologies including techniques that remove CO2 from flue streams, increase power efficiencies, and lower energy-production costs.

The newly patented technologies support NETL’s mission to address challenges associated with the continued use of our nation’s fossil energy resources. Their commercialization would ultimately benefit taxpayers by increasing the efficiency of energy production, cutting its cost, lowering emissions, and enhancing America’s energy independence.

NETL’s Public Affairs and Strategic Outreach Division manages the laboratory’s patents and its efforts to move intellectual property out of the laboratory through the formation of strategic partnerships. The novel ideas, products, and processes protected in the patents are transferred to industry and public- and private-sector organizations through agreements such as licenses and cooperative research and development agreements. Such agreements are designed to facilitate the transfer of the laboratory’s intellectual property into the marketplace.

The technologies patented by NETL in 2014 are now available for commercialization. Below are brief summaries of the newly issued patents.

Apparatus And Process For the Separation of Gases Using Supersonic Expansion and Oblique Wave Compression (U.S. Patent Number 8,771,401)—Current methods of separating carbon dioxide (CO2) from multi-component gas streams involve compression and refrigeration techniques to condense CO2, which require significant expenditures of energy. This invention applies two aerodynamic techniques to both cool the gas and change the phase of the CO2 from a vapor to a solid, reducing the amount energy required for CO2 separation.

Solid Oxide Fuel Cells having Porous Cathodes Infiltrated with Oxygen-Reducing Catalysts (U.S. patent number 8,802,316)—Solid oxide fuel cells (SOFCs) offer clean, secure, and sustainable energy because of their high energy efficiency, fuel flexibility and the intrinsic separation of the fuel and air streams, making carbon capture inexpensive and easily accomplished. This invention describes a cathode modification that will significantly increase SOFC kinetics, reducing the cost of the cell at current operating temperatures.

Regenerable Immobilized Aminosilane Sorbents for Carbon Dioxide Capture (U.S. Patent Number 8,834,822)—In order to capture CO, from flue gas, it must first be separated. This invention describes an improved method of CO2 separation using immobilized amine sorbents. The sorbents have increased stability under high humidity and temperature conditions, such as those found in flue gas streams. The use of these sorbents will allow for maximum CO2 removal while reducing the cost of CO2 capture.

Poly (Hydroxyl Urethane) Compositions and Methods of Making and Using the Same (U.S. Patent Number 8,912,303)—Polyurethanes are polymers that are joined together by urethane (carbamate) linkages. Polyurethanes have many commercial applications, including adhesives, coatings, sealants, and binders. There has been an effort to minimize the use of toxic isocyanate chemistry in the manufacturing of polyurethanes. This invention uses an alternative approach, using CO2-derived organic carbonates to provide a synthetic approach that is efficient, simple, flexible, and scalable. This approach does not utilize any isocyanate chemistry.

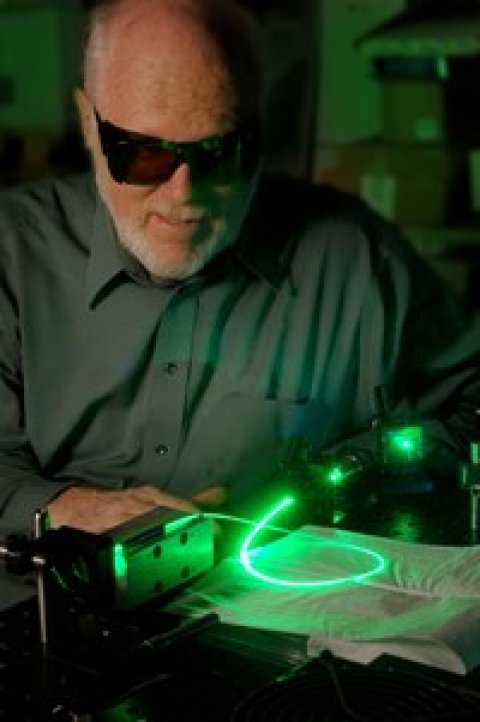

A Method and Device for Remotely Monitoring an Area Using a Low Peak Power Optical Pump (U.S. Patent Number 8,786,840)—The ability to detect CO2 leakage from carbon storage sites is critical to ensure that the gas will remain safely and permanently stored underground. This invention uses miniaturized laser sensors with optical fibers as a CO2-leakage detection system. The sensors use an optical system that is resistant to the extreme heat and pressure of the down-hole environment, allowing it to efficiently and cost-effectively monitor groundwater and air quality.

Production of Methane-Rich Syngas from Hydrocarbon Fuels Using Multifunctional Catalyst/Capture Agent (U.S. patent number 8,920,526)—Gasification is an efficient way to use fossil fuels because the material is reacted at high temperatures without combustion to generate syngas, a gas mixture that can be used to make methane. Methane-rich syngas can then be used to power high-efficiency SOFCs for power generation. This invention describes the uses of catalysts to facilitate the production of methane-rich syngas at the same temperature as the operating temperature of the SOFC.

- U.S. Patent Number 8,658,561 describes a more efficient, layered solid sorbent in which the first layer captures a portion of the gas and the second layer transports the gas out of the flue-gas stream. The new sorbents have the potential to capture more CO2 at a lower cost.

- U.S. Patent Number 8,889,589 describes the method to prepare the solid sorbent materials.

Constant Pressure High Throughput Membrane Permeation Testing System (U.S. Patent Number 8,821,614)—Membrane technology has demonstrated tremendous potential for gas separation. Membranes are mechanically simple and can be made from a wide variety of organic and inorganic materials, but the evaluation of so many different types of membranes is laborious and time consuming. This invention allows researchers to test the gas permeance—the ability of gas to penetrate a solid—of up to 16 membranes simultaneously in a cartridge-based cell block. It further uses a mixed-gas feed stream, which simulates the conditions of an industrial application.

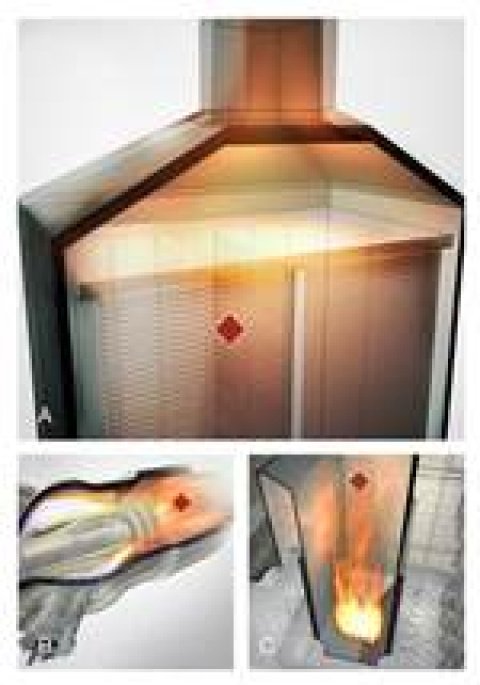

Basic Refractory and Slag Management for Petcoke Carbon Feedstock in Gasifiers (U.S. Patent Number 8,703,021)—Gasification systems use coal, petcoke, or mixtures of both as carbon feedstocks. Impurities in these materials form ash, which becomes molten and coalesces during gasification, forming slag. The slag flows down the side walls of the gasifier, causing wear on the refractory lining. Higher temperatures increase that wear. This patent indicates that controlling slag chemistry can lower slag viscosity at a specific temperature, which allows for lower gasification temperature and reduces refractory wear. The patent also indicates that if a basic refractory lining is used in a gasifier in combination with slag chemistry control, lower refractory wear will occur. Benefits from controlling slag chemistry and the use of a basic refractory lining will result in increased gasifier availability and greater process efficiency.

- Nanocomposite Thin Films for Optical Gas Sensing (U.S. patent number 8,741,657)

- Electrically Conducting Metal Oxide Nanoparticles and Films for Optical Sensing Applications (U.S. patent number 8,836,945)

- Plasmonic Transparent Conducting Metal Oxide Nanoparticles and Nanoparticle Films for Optical Sensing Applications (U.S. patent number 8,638,440)

Method of CO2 Removal from a Gaseous Stream at Reduced Temperature (U.S. patent number 8,888,895)—Sorbents have shown great potential for CO2 removal from flue-gas streams, but when moisture is present in the stream, higher temperatures are required to regenerate the sorbent. This invention describes a way of regenerating the moisture removal sorbent using the waste hot gas stream. Moisture removal is conducted prior to the CO2 removal with a solid sorbent. This allows the moisture removal step to take place at lower temperatures, making the entire CO2 removal process less energy-intensive and more cost-effective.

Method of Purifying a Gas Stream Using 1,2,3-Triazolium Ionic Liquids (U.S. patent number 8,906,135)—Carbon capture and storage from fossil fuel–based power generation systems is a critical component of strategies to reduce the rise in atmospheric CO2 concentrations. Currently available carbon-capture processes significantly reduce efficiency and increase electricity cost. This invention addresses a new class of ionic liquids—organic salts that are liquid at room temperature—that could lead to more efficient and economical processes to capture CO2. The ionic liquids covered in this invention result in compounds with increased CO2 solubility and thermal stability, which facilitates their use for CO2 capture at high temperatures.