--These projects are inactive--

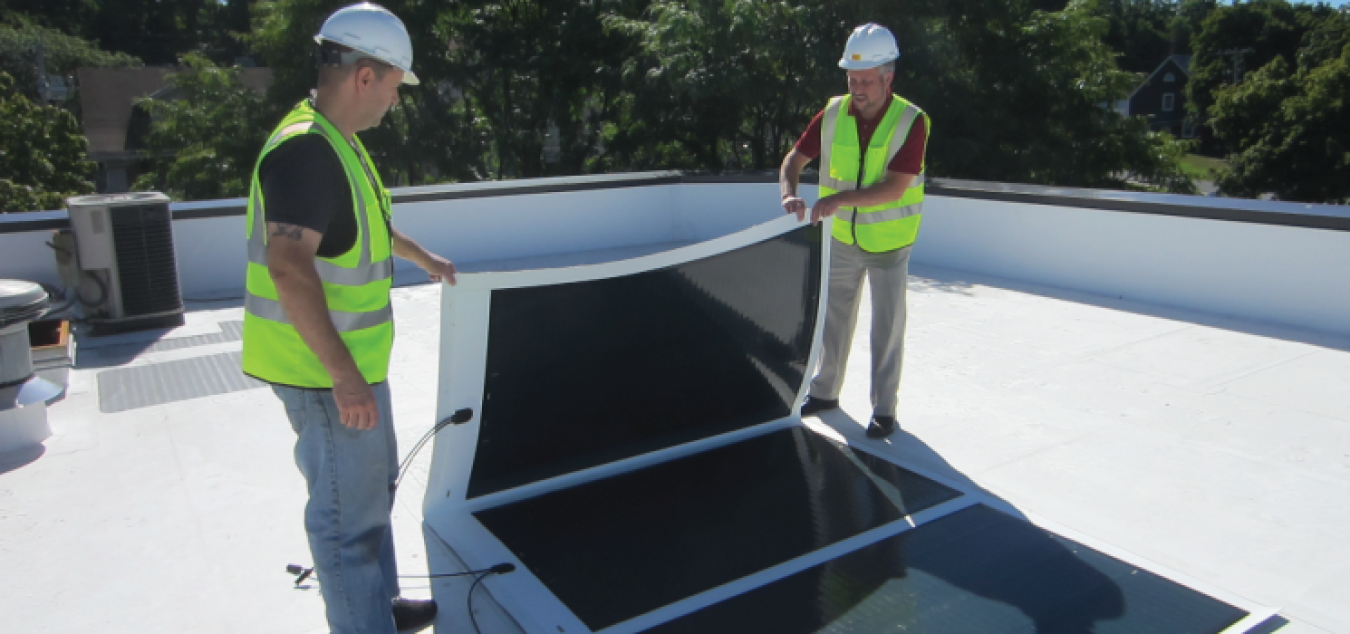

The Lightweight Integrated Module Package is a flexible, foldable, and modular solar panel assembly designed for quick and simple installation on flat commercial and industrial roofs without the need for heavy ballast. Photo by SUNY Polytechnic Institute.

The Photovoltaic Manufacturing Initiative (PVMI) invests in manufacturing-focused research projects that strengthen the competitiveness of the photovoltaic (PV) module industry and supply chain in the United States. PVMI also establishes manufacturing development facilities that provide infrastructure for demonstrating, testing, optimizing, and manufacturing new technologies with reduced capital requirements. These awards were announced on April 5, 2011.

Approach

PVMI focuses on coordinating teams in industry and academia to generate new solutions for PV manufacturing that reduce the cost of module-scale production. It establishes joint-use facilities that provide PV companies and suppliers access to equipment and services that accelerate development of new PV technologies while making the transition to domestic, commercial-scale production. The partnerships strongly leverage industry, state, and local funds and are expected to grow over time, adapting to market conditions and continuously adding new industrial and academic participants.

Objectives

PVMI will help the solar power industry overcome technical barriers and reduce costs for PV installations. It will also help the U.S. regain the lead in the global market for solar technologies, providing support for clean energy jobs for years to come.

Teams

Bay Area PV Consortium

Location: Stanford, California

The Bay Area PV Consortium (BAPVC) funds industry-relevant research and development to impact high-volume PV manufacturing using a competitive selection process open to all universities. This project, managed by Stanford University and the University of California, Berkeley, develops and tests innovative new materials, device structures, and fabrication processes necessary to produce cost-effective PV modules in high volumes. The research advances technologies that bring down manufacturing costs and improve device performance characteristics to help achieve SunShot cost targets. Member companies determine the specific topics for research and development to ensure close alignment with industry and manufacturing needs, then review individual projects as they progress.

Solar Rochester Consortium

Location: Albany, New York

Solar Rochester is creating a first-of-a-kind PV manufacturing development facility (MDF) that will support the growth and maturation of a strong, domestic PV manufacturing industry. This facility will ensure industry participants have access to the cutting-edge manufacturing equipment and production expertise needed to accelerate the transition of innovative technologies from research and development into commercial manufacturing. This project is being completed through an open access environment, which can accelerate the process of moving products from labs into production for universities, colleges, and national laboratories. This includes protecting companies’ intellectual property, enabling them to develop proprietary, innovative technologies while removing barriers to market entry.

The MDF will support silicon-based PV technologies, providing a range of services and equipment, including complete manufacturing lines, access to individual tools, manufacturing experts, secure fabrication space for users’ proprietary tools, and pilot production services in an intellectual property (IP) secure environment. Companies will work in the MDF fabrication space, collaboratively with MDF staff, to achieve the same touch-and-feel development experience as obtained in their own labs.

U.S. Photovoltaic Manufacturing Consortium

Location: Albany, New York, and Palm Bay, Florida

Managed by SEMATECH, the U.S. Photovoltaic Manufacturing Consortium (PVMC) is coordinating an industry-driven initiative to accelerate the development, manufacturing, and commercialization of next‐generation copper indium gallium diselenide (CIGS) thin film PV manufacturing technologies, tools, and materials. PVMC seeks to drive down the cost and risk of bringing CIGS technologies to the marketplace. In partnership with the PV industry, PVMC will develop a PV Technology Roadmap to guide the industry in assessing research and development needs and opportunities for innovation. In addition, PVMC will operate complementary programs to foster new PV technologies and firms, and to develop the U.S. PV workforce.

PVMC with its major partner, the College of Nanoscale Science and Engineering at the State University of New York at Albany, is establishing manufacturing development facilities that PV companies and researchers can use for product prototyping, demonstration, and pilot‐scale manufacturing to evaluate and validate CIGS thin film and PV manufacturing technologies. PVMC is also working with the University of Central Florida to develop cost-effective in-line measurement and inspection tools to enable increased PV manufacturing yield for silicon-based technologies.

Learn more about SETO's other funding programs.