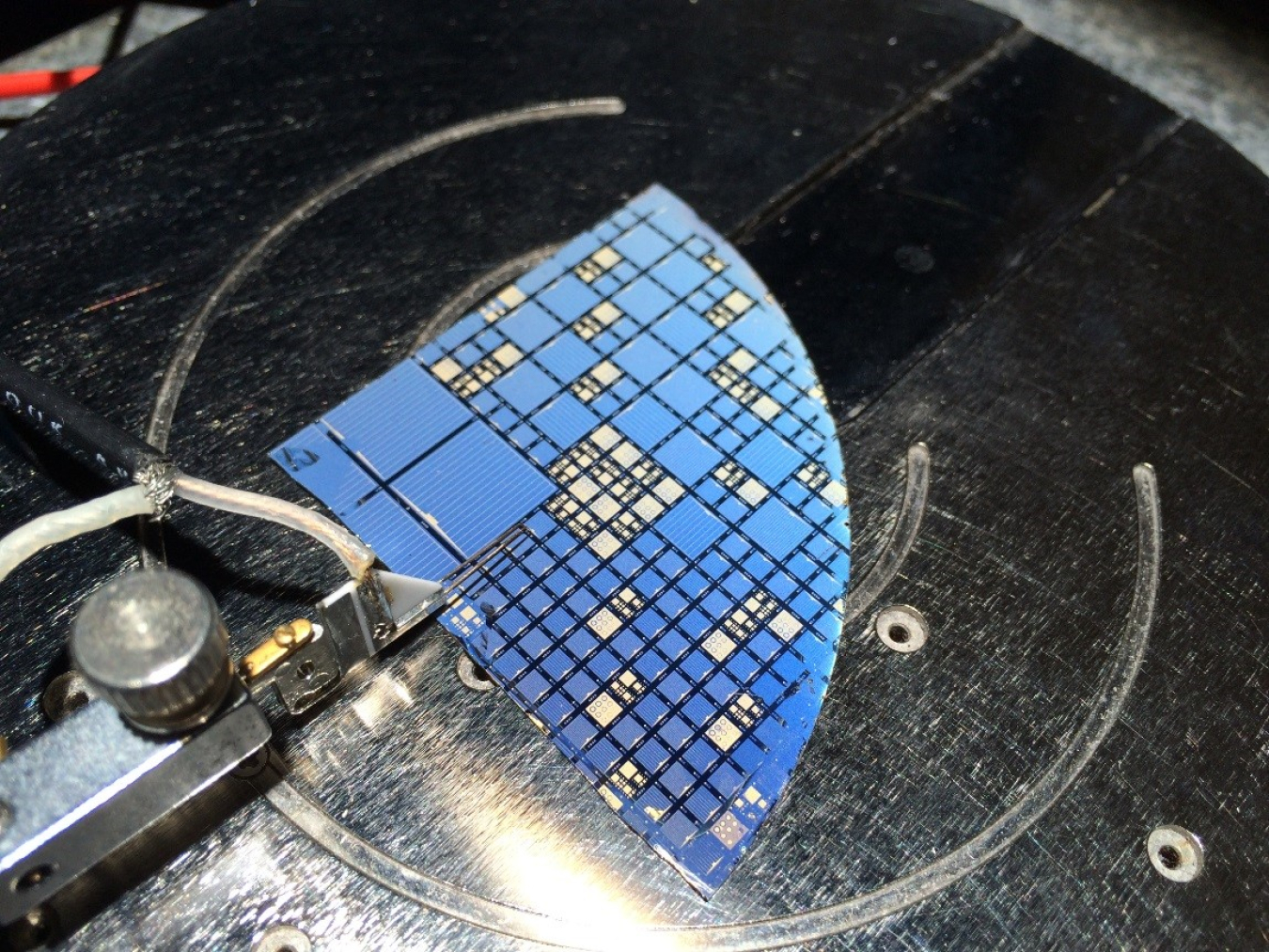

III-V/Si multi-junction solar cells developed at Ohio State University undergo illuminated current-voltage testing.

The solar cells found in today’s typical photovoltaic (PV) solar panels convert about 20% to 23% of the light that passes through them into electricity, leaving nearly 80% of the their possible energy conversion behind. Thus, improving solar cell efficiency is always an important topic for PV researchers. Normally made from silicon, scientists believe that using different materials or a combination of materials could be a major key to boosting energy conversion and improving efficiency in solar cells.

With support from the SunShot Initiative’s Foundational Program to Advance Cell Efficiency (F-PACE), Ohio State researchers created a prototype solar cell by layering gallium indium phosphide (GaInP) and gallium arsenic phosphide (GaAsP) with silicon (Si). Called an epitaxial Si triple-junction solar cell, the materials are connected in tandem within each cell in a single process. The prototype establishes a path to potentially creating solar cells that have efficiency levels of 40% or greater and would cost a fraction of the current state-of-the-art multijunction solar cells.

For decades researchers have experimented with epitaxially combining III-V and silicon solar cell structures, but Ohio State’s multi-junction solar cell research is the first to come to fruition, and it already has commercial prospects. This SunShot-funded research team was the first to successfully demonstrate the production of high efficiency GaInP/GaAsP/Si and GaAsP/Si tandem cells in a single process. Along the way, the team also was able to achieve several notable science and engineering developments including: III-V/Si integration process, novel Si subcell, GaInP and GaAsP integrated III-V subcells, high-performance tunnel junctions, identification and mitigation of process-induced Si lifetime degradation, and new rapid materials characterization methods.

Connecting materials using a single process is notoriously difficult, but important for eventually commercializing these solar cells. Because Si PV manufacturing produces 95% of solar cells and Ohio State’s process is compatible with current Si PV manufacturing techniques, the new cells could quickly penetrate the current PV market. Moreover, because these new cells could use existing supply chains and distribution networks, this would prevent unnecessary expenditures on new manufacturing equipment. These low-cost, highly efficient solar cells have the potential to have an incredible impact on the current PV market and enable the industry to soon meet or even exceed current levelized cost of energy targets for making solar energy cost-competitive with other forms of electricity.

Learn more about the SunShot Initiative and its photovoltaics research and development work.