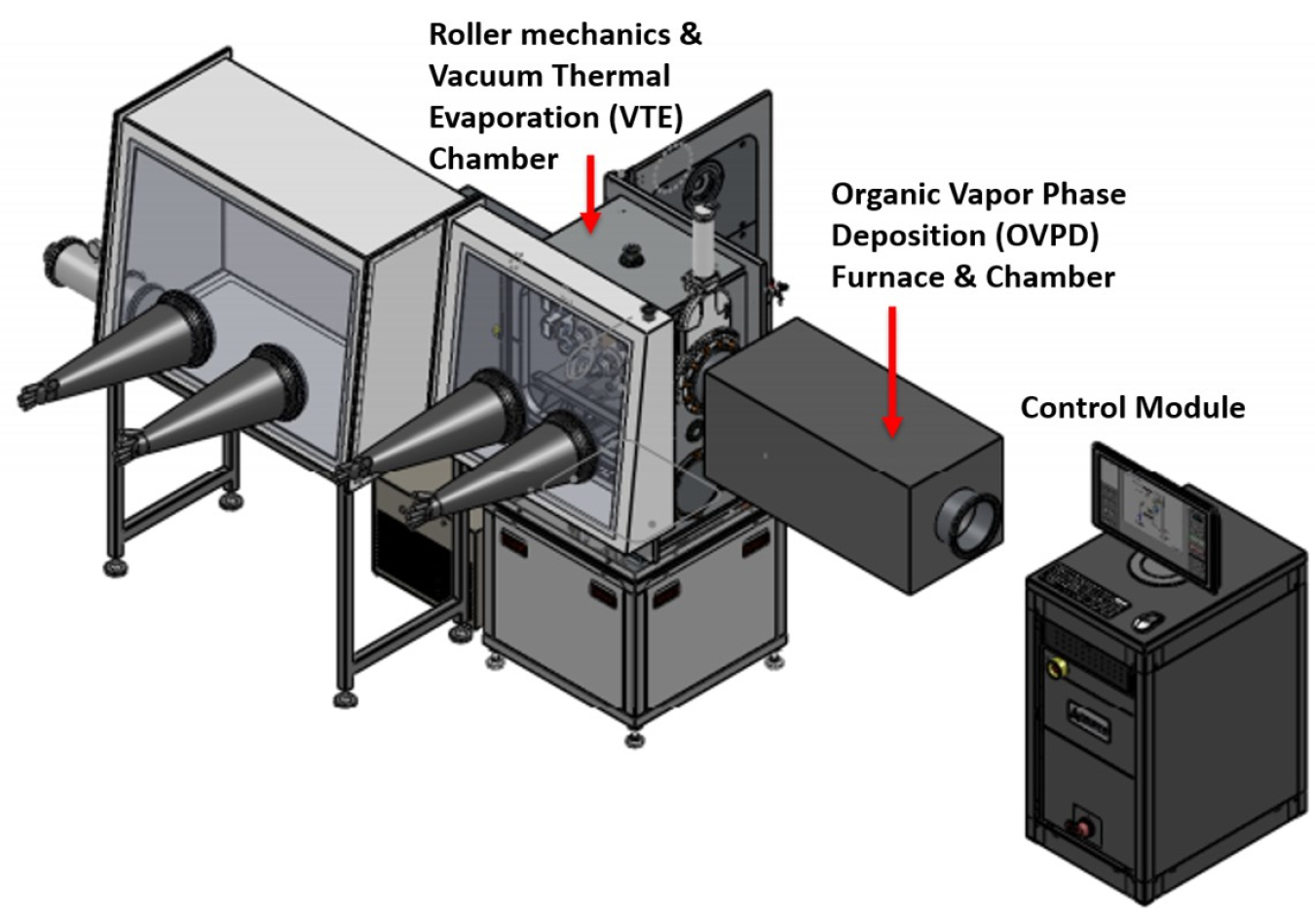

UNIVERSITY OF MICHIGAN RESEARCHERS ARE DEVELOPING A ROLL-TO-ROLL PROCESS FOR OLED MANUFACTURING

Researchers at the University of Michigan are teaming up with OLED manufacturer Universal Display Corp. (UDC) to develop a low-cost roll-to-roll (R2R) process for the manufacturing of flexible OLED devices to be used in general illumination. Currently, white OLEDs—which are used for general illumination—are primarily batch-produced on relatively thick, brittle glass substrates, with limited throughput and at high cost. The R2R process being developed will produce, at high speed and reduced cost, a continuous output of encapsulated flexible, lightweight OLED lighting fixtures at a projected cost of <$10/klm. (September 2020) Learn more.

QUANTIFYING OUTDOOR LIGHTING’S HEALTH IMPACTS IN A REAL-WORLD SETTING AT VIRGINIA TECH TRANSPORTATION INSTITUTE

Studies have shown a strong link between human light exposure and melatonin levels, which in turn impact sleep, alertness, and general health. With DOE funding, researchers at Virginia Tech Transportation Institute, in a partnership with Thomas Jefferson University, have studied the effects of outdoor lighting on melatonin levels in realistic roadway environments. (September 2020) Learn more.

RESEARCHERS AT PENN STATE UNIVERSITY ARE IMPROVING OLED PERFORMANCE THROUGH SEMICONDUCTOR DILUTION

Although the conversion of electrical current to photons is very efficient in OLED lighting panels, extracting the light remains a major challenge. The basic problem arises from the high refractive index of the layers in which the photons are created. Most of the photons are reflected before they can escape into air, which has a much lower refractive index. With the help of DOE funding, researchers at Penn State University have developed an innovative way to reduce the refractive index of the emitting layers of OLEDs. (September 2020) Learn more.

LUMILEDS IS DEVELOPING A HIGH-LUMINANCE, HIGH-EFFICACY LED PLATFORM FOR DIRECTIONAL LIGHTING

With the help of DOE funding, researchers at Lumileds are working to develop a high-luminance, high-efficacy LED platform for directional lighting applications. The platform will consist of a range of surface-emitting chip-scale packages based on a 1 mm2 die with minimal package size to facilitate packing in dense arrays. The project will demonstrate improved efficacy at both the LED level and the module level. (September 2020) Learn more.

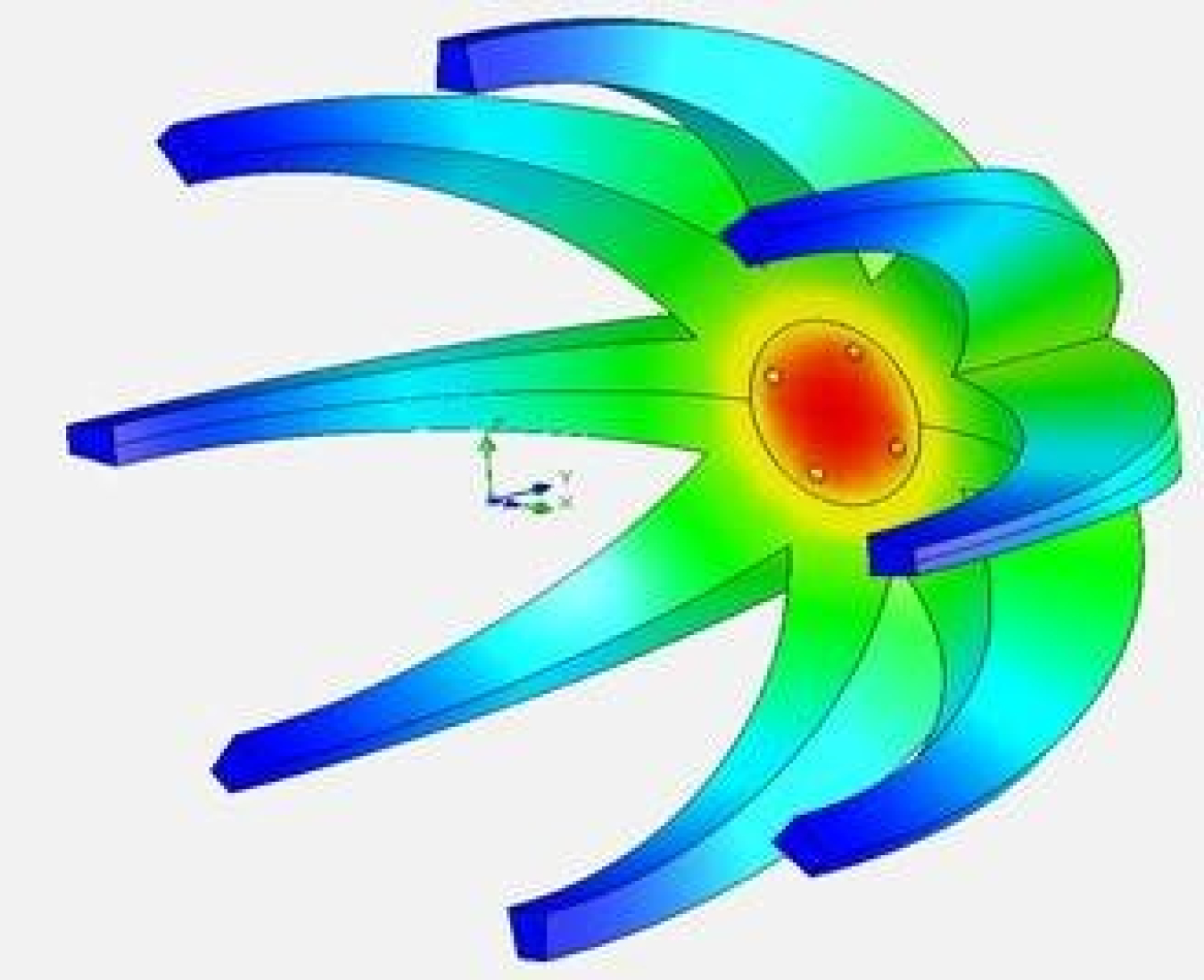

EATON IS DEVELOPING AN ADDITIVELY MANUFACTURED LED LUMINAIRE

Eaton is developing a fully integrated approach to manufacturing LED luminaires, leveraging additive-manufacturing technology. Carried out in partnership with the Lighting Research Center at Rensselaer Polytechnic Institute and the Xerox Research Centre of Canada, the project is investigating additive-manufacturing approaches that will significantly reduce cost, eliminate manufacturing waste, and improve luminaire efficacy. Targets include a 50% reduction in materials usage, process steps, and first cost, while achieving an efficacy of 130 lm/W. So far, materials usage has been reduced by 50%, process steps by 30%, and process costs by 25%. (July 2020) Learn more.

RESEARCHERS AT GEORGIA TECH PAVE THE PATH TO LOWER COSTS BY DEVELOPING EFFICIENT EMITTERS FOR OLEDS WITH SIMPLIFIED GEOMETRY

With the help of DOE funding, researchers at the Georgia Institute of Technology have developed a new generation of organic emitters that challenge conventional wisdom by yielding high performance when used as neat single-component layers in OLED devices with simplified geometry. The team's approach is based on the search for new molecules within the known class of materials that exhibit thermally activated delayed fluorescence (TADF), which provides an alternative to phosphorescent emission. (September 2019) Learn more.

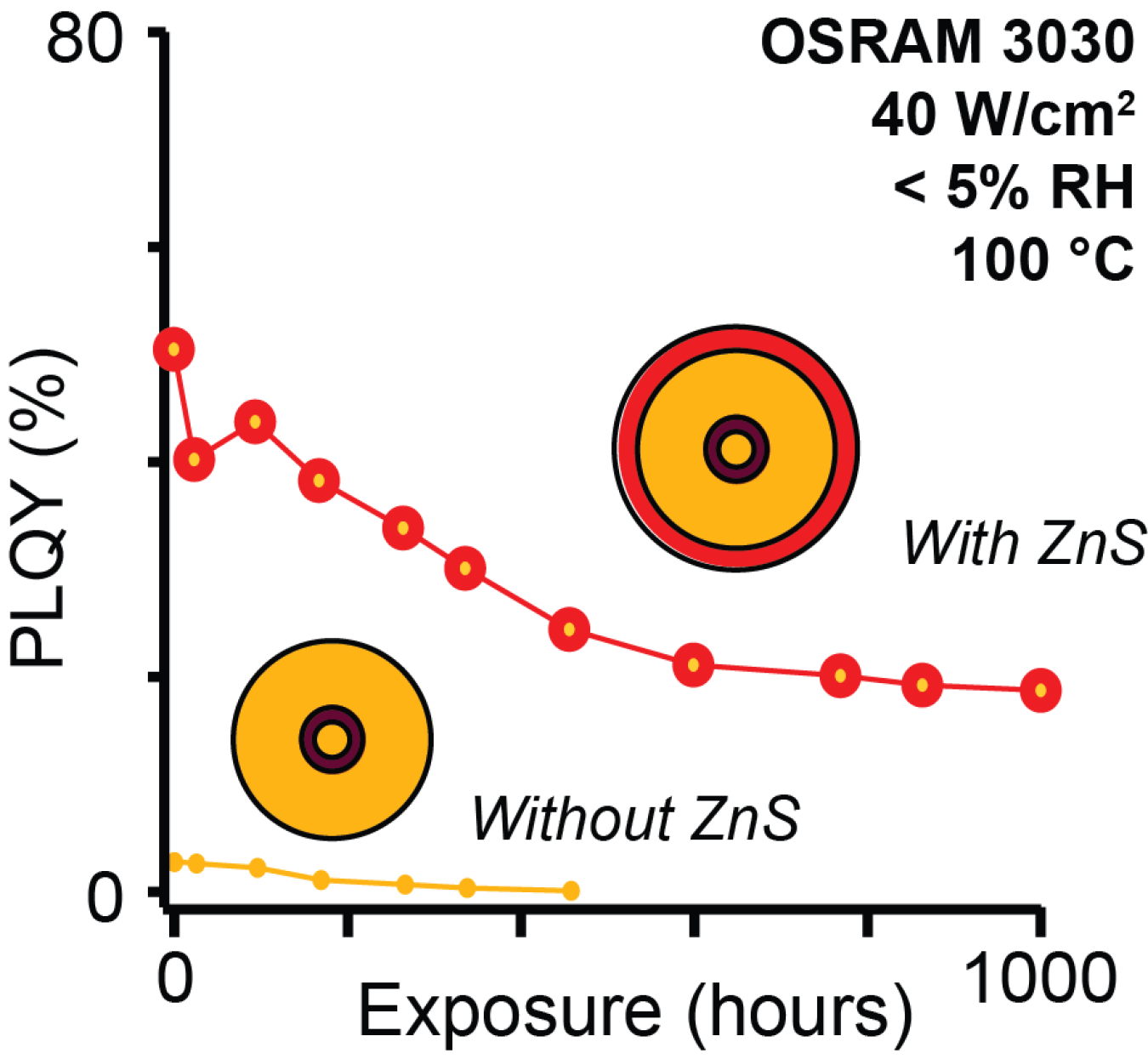

RESEARCHERS AT COLUMBIA UNIVERSITY IMPROVE MANUFACTURING EFFICIENCY OF WARM-WHITE LEDS

With the help of DOE funding, researchers at Columbia University, OSRAM Opto Semiconductors, and Lawrence Berkeley National Laboratory have developed a new process to synthesize red-emitting quantum dots in a single-step manufacturing process. These materials achieve efficient red emission on LED lighting packages that achieve state-of-the-art reliabilities under the harsh conditions necessary for commercial adaptation. (September 2019) Learn more.

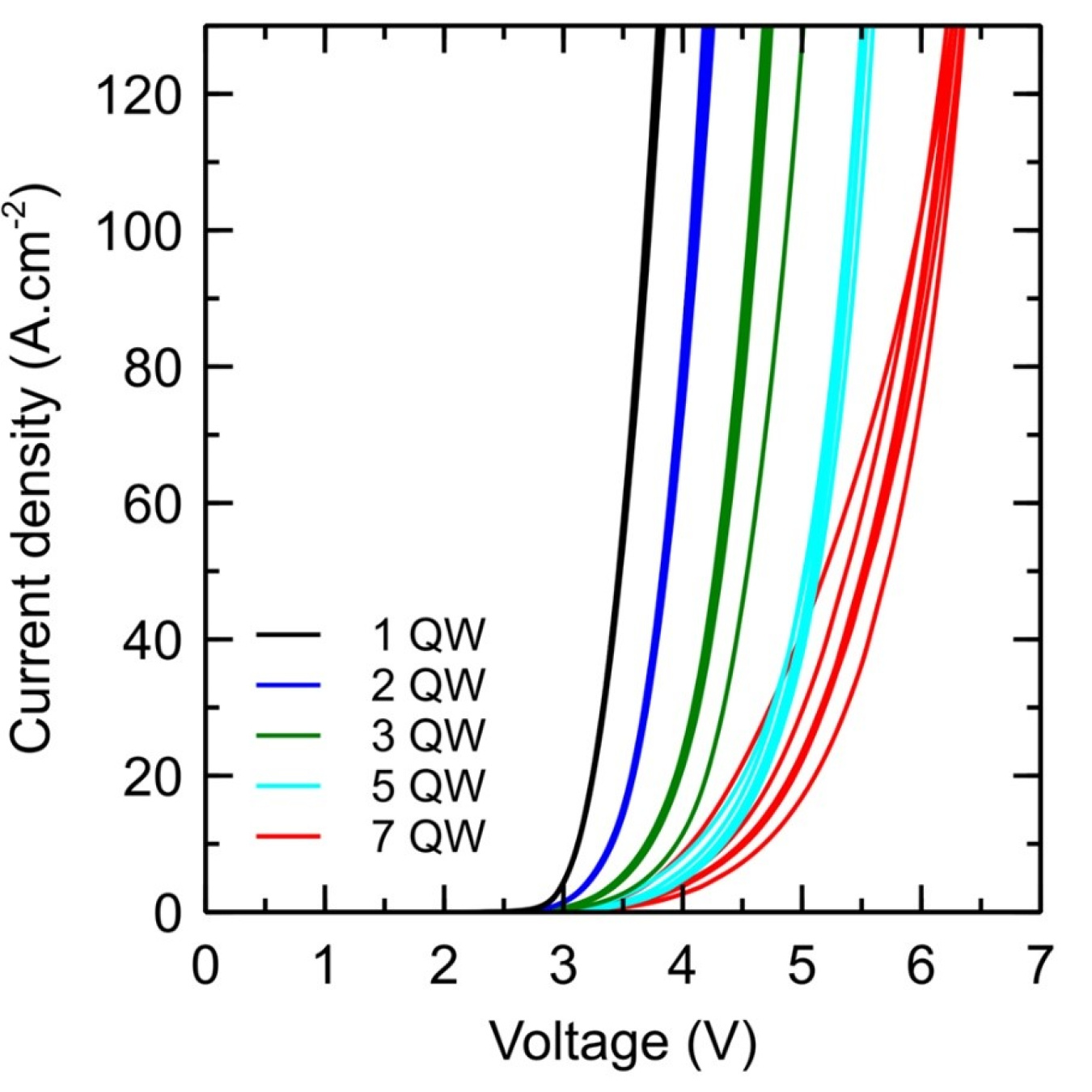

RESEARCHERS AT THE UNIVERSITY OF CALIFORNIA AT SANTA BARBARA DISCOVER A KEY TO IMPROVING THE EFFICIENCY OF GREEN AND AMBER LEDS

Using a computational approach based on landscape theory, researchers at the University of California at Santa Barbara have identified key factors in the LED’s semiconductor layer structure that impact the forward-voltage performance of green LEDs. The findings indicate that careful design of the semiconductor layers in or surrounding the LED active region is essential to avoid excess voltage in green LEDs. The number of quantum wells, the percentage of aluminum in the quantum barriers, and the InGaN/GaN superlattice structure below the LED active region can be optimized to reduce the forward-voltage penalty in green LEDs. (September 2019) Learn more.

THE NATIONAL RENEWABLE ENERGY LABORATORY ESTABLISHES A NEW METHOD TO ACHIEVE HIGH-EFFICIENCY AMBER AND RED LEDS

Most mass-produced red and amber LEDs on the market today are based on the elements aluminum, gallium, indium, and phosphide (abbreviated as AlGaInP when used in combination). The efficiency of these AlGaInP LEDs is limited by the loss of injected electrons through several pathways that are intrinsic to that kind of material system. With funding from DOE, researchers at the National Renewable Energy Laboratory (NREL), MicroLink Devices, and the South Dakota School of Mines and Technology have demonstrated that these pathways, and the losses they entail, can be reduced by switching to a related material system that’s based on aluminum, indium, and phosphide (AlInP). This new approach has the potential to enable improvements in amber (~580-590 nm) and red (~610-620 nm) LED efficiencies. (September 2019) Learn more.

SANDIA RESEARCHERS DEMONSTRATE TUNNELING-ENABLED HIGH-EFFICIENCY, HIGH-POWER, MULTI-JUNCTION LEDS

With the help of funding from the U.S. Department of Energy, a team of researchers at Sandia National Laboratories and The Ohio State University have demonstrated the feasibility of using multi-junction cascaded LEDs to increase external quantum efficiency (EQE, a measure of how efficient the LED is) at fixed current density. This approach avoids the common phenomenon known as current droop, in which the efficiency of the LED decreases as the electrical current density increases. Current droop remains a significant barrier to LED efficiency. (September 2019) Learn more.

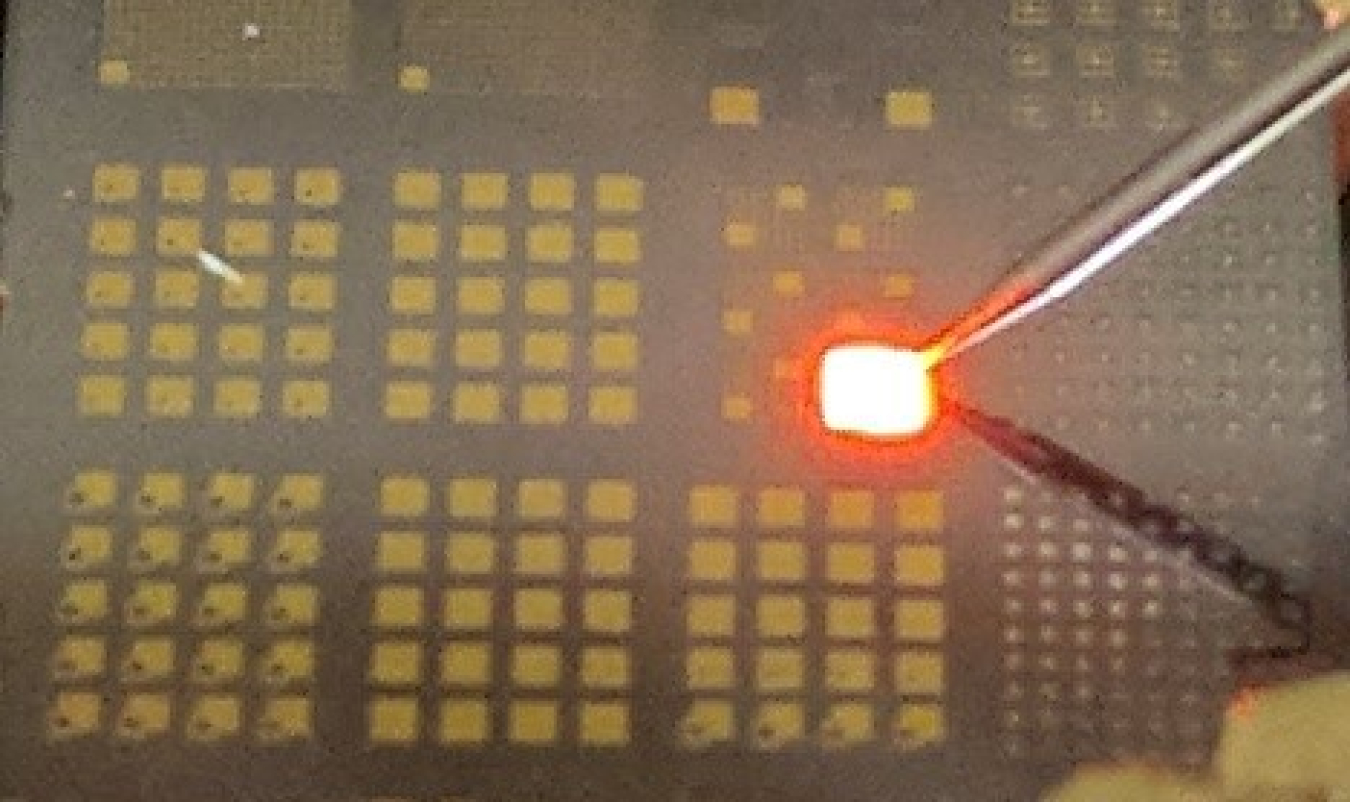

LUMILEDS FURTHER EXCEEDS EQE MILESTONE IN AMBER LIGHT

With funding from DOE, researchers at Lumileds have achieved, in a laboratory prototype, an amber LED with external quantum efficiency (EQE) of 22% at current density of 35 A/cm2 and junction temperature of 25°C. Efficient red and amber LEDs are essential building blocks for next-generation lighting products, enabling the ultimate DOE efficacy targets and spectral design freedom in color-mixed white and color-tunable lighting applications. (September 2019) Learn more.

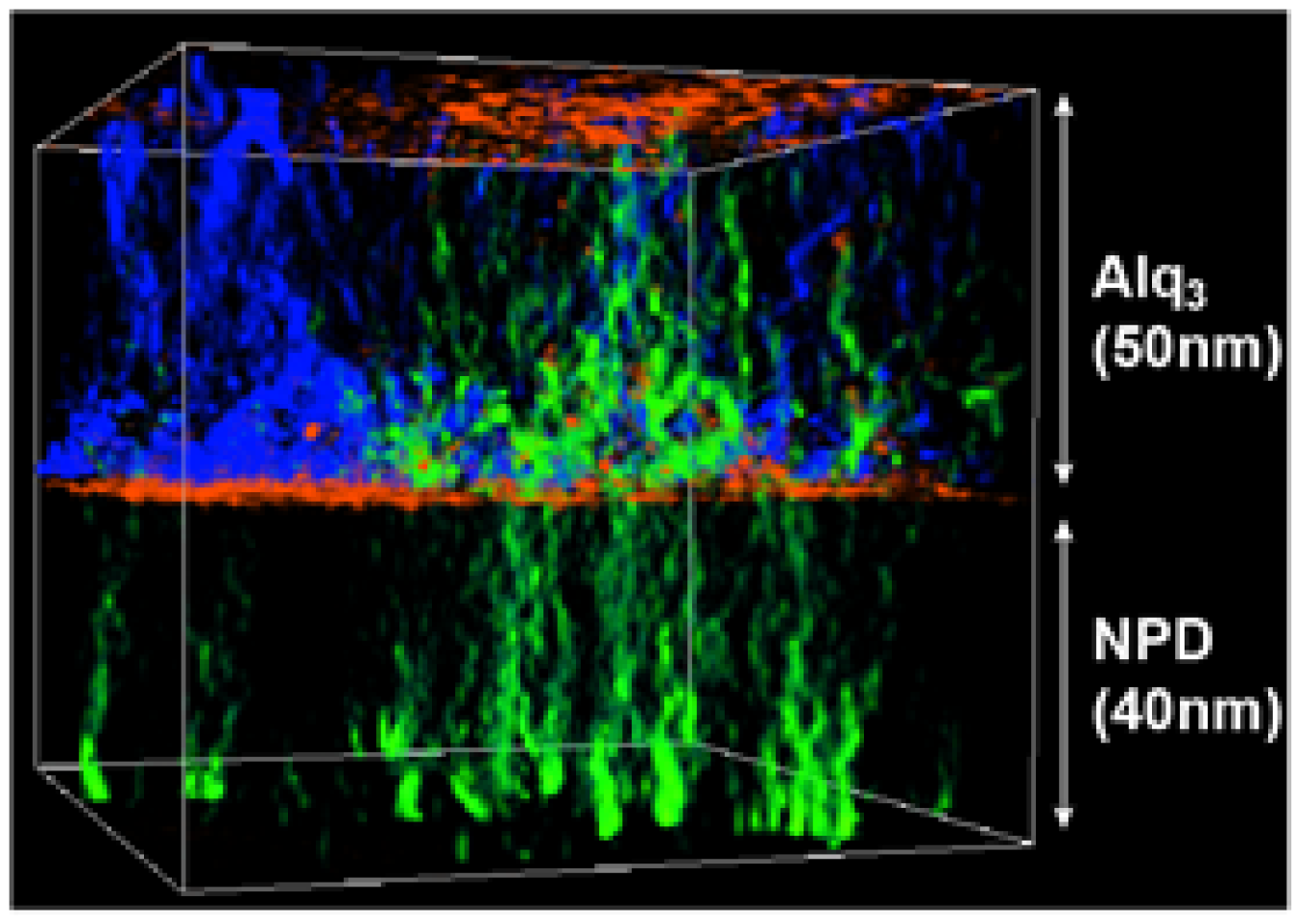

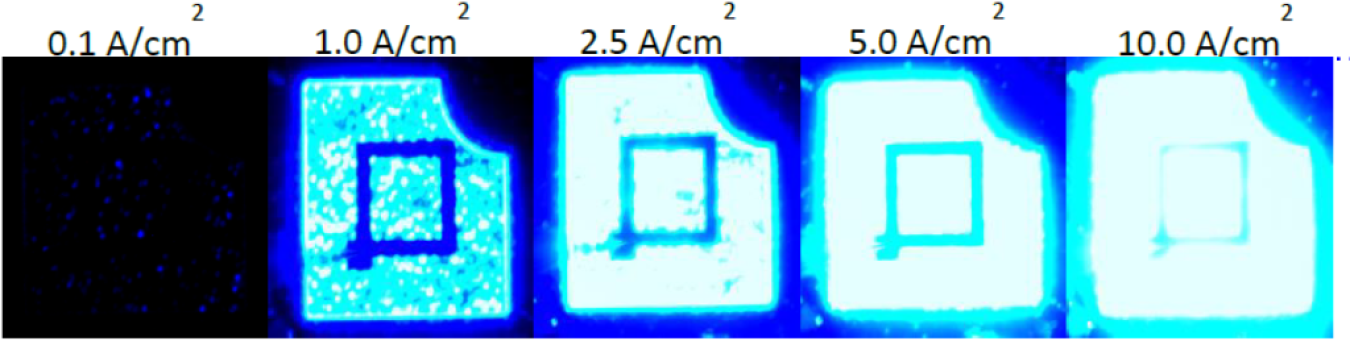

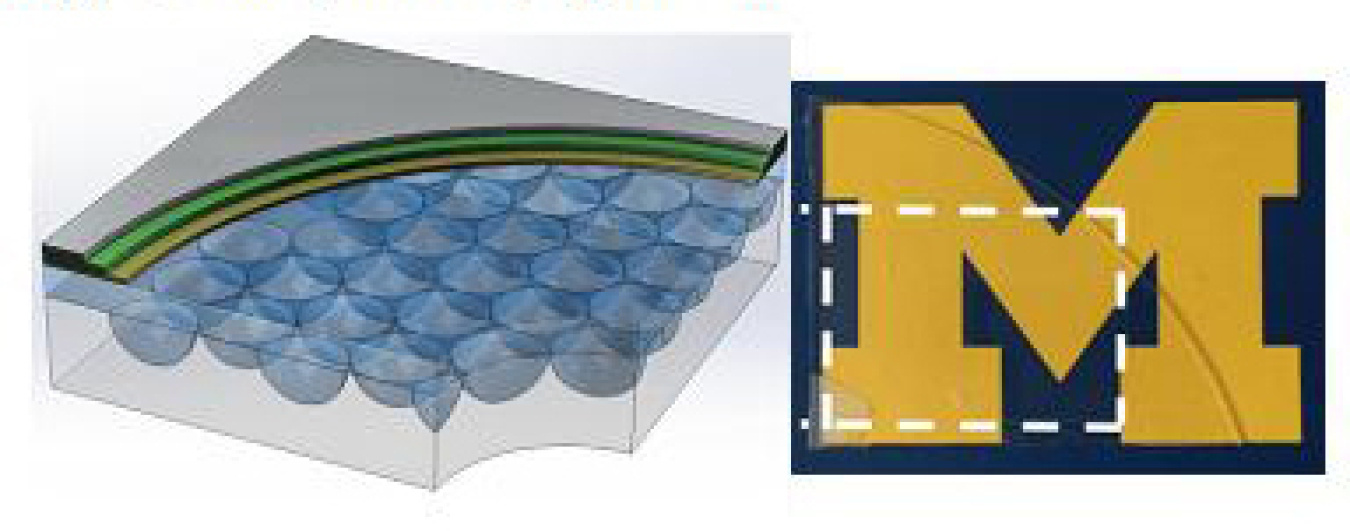

UNIVERSITY OF MICHIGAN DEVELOPS A METHOD TO INCREASE LIGHT EXTRACTION IN WHITE OLEDS

With the help of DOE funding, researchers at the University of Michigan have developed a method to increase the light extraction in white organic light-emitting diodes (OLEDs), thereby improving their performance and reducing their cost. Based on a sub-electrode microlens array, the method has increased the external quantum efficiency (EQE, the ratio of photons emitted from an OLED to the electrons injected from the electrodes) of electrophosphorescent white-emitting OLEDs (WOLEDs) to 70% – a significant improvement over past results. (July 2019) Learn more.

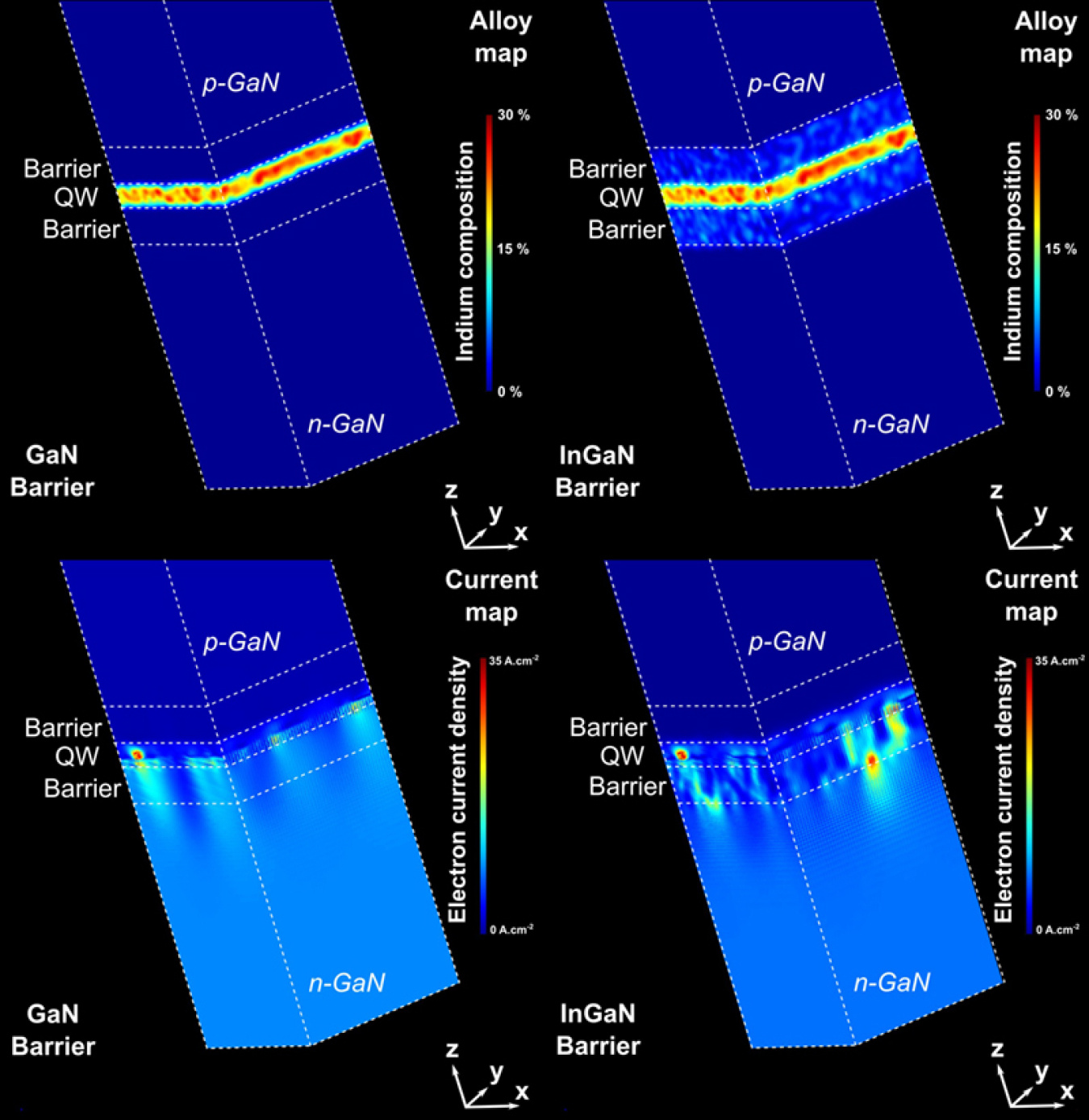

RESEARCH TEAM LED BY THE UNIVERSITY OF CALIFORNIA AT SANTA BARBARA DEVELOPS A SIMULATION TOOL TO HELP IMPROVE THE PERFORMANCE OF GREEN LEDS

Simulations are used to predict the performance and behavior of a system instead of relying solely on experimental understanding – thus reducing cost and shortening development time. With the help of DOE funding, researchers at the University of California at Santa Barbara, in collaboration with those at National Taiwan University, the University of Minnesota, and France’s École Polytechnique, have developed a numerical tool that allows the 3D simulation of Group III nitride devices. (May 2019) Learn more.

Return to Research Highlights