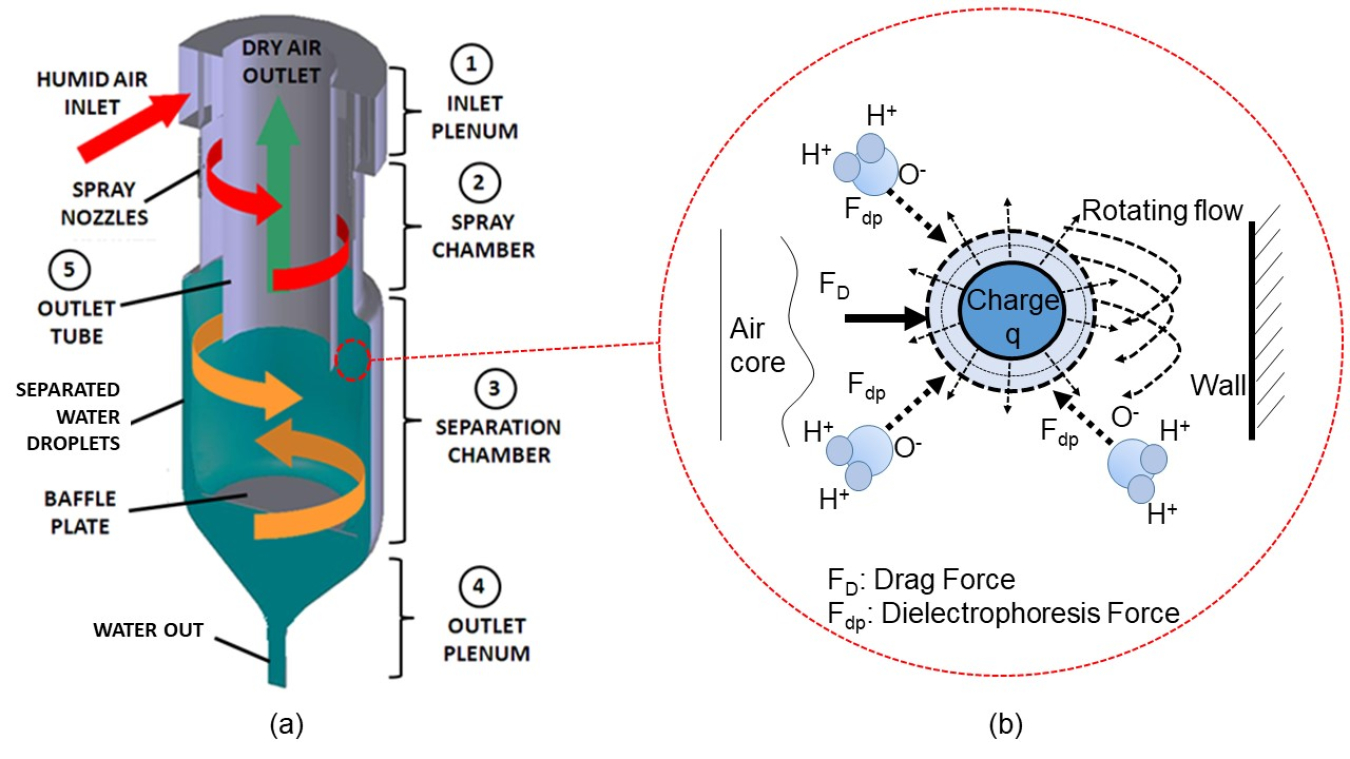

Figure 1: (a) rendering of the Electrospray Vortical Flow eXchanger (EVFX), (b) zoom out of the charged droplet attracting water vapor molecules, moving and growing in a microgravity environment of a vortex.

Lead Performer: Auburn University – Auburn, AL

Partners:

-- Advanced Cooling Technologies Inc. – Lancaster, PA

-- Johnson Controls Inc. – Milwaukee, WI

DOE Total Funding: $1,457,470

Cost Share: $372,479

Project Term: April 1, 2020 – September 30, 2023

Funding Type: Funding Opportunity

Project Objective

In this project, Auburn University, in partnership with Advanced Cooling Technologies Inc. and Johnson Controls Inc., will develop an Electrospray Vortical Flow eXchanger (EVFX) for Separating Sensible and Latent Cooling (SSLC) in A/C systems. The new air handler consists of small electrically charged water droplets released inside optimal velocity-generated air rotating vortexes. The charged droplets attract water vapor molecules and travel inside the vortex, effectively wiping out the humidity from the air. As the vapor molecules collapse on the droplets’ surface, the droplets’ initial electrical charge decreases with time due to the neutralization of the ions. The vortical flow cyclone separates largest droplets from the air, and these droplets collect at the outer wall and move to the bottom of the tube. Then, these droplets are recirculated back to the electrospray, where they are atomized, electrically recharged and sprayed in the air vortex for the next cycle.

Project Impact

The project technology will serve as electrostatic water vapor separation technology to shift building latent loads toward sensible loads. This is an in-kind type technology in which there are only parasitic electric power for pumps and fans. No need to generate high electrostatic field and no condensation walls. No physical filters, no membranes, and no need of regeneration. No fouling. Not corrosive. No water consumption. Not toxic. No flammability issues. Excellent part-load performance due to fast and modular electrospray technology. Reduced weight relative to enthalpy wheels. Easy to be integrated as add-on component in air handling units for retrofitting HVAC systems and in commercially available air handlers.

The demonstration unit from this project will spark new dehumidification systems that can be used in buildings, transportation AC systems, even industrial facilities and warehouses, especially the ones located in hot and humid climates, for indoor air quality and humidity control. If successful, this in-kind technology has the potential to both reduce the utility costs associated with air conditioners by reducing the kWh electricity used, and improve the indoor air quality, compared to standard vapor-compression air conditioners.

Contacts

DOE Technology Manager: Payam Delgoshaei

Lead Performer: Lorenzo Cremaschi

Related Publications

Cremaschi, 2019, Electrospray Dehumidification for High Energy Efficiency of Buildings, Auburn University Research Symposium, Auburn, AL (USA), October 4.

Cremaschi, 2020, Enhanced Air Dehumidification through Electrically Charged Rotating Vortexes and Vapor Capturing Electrostatic Droplets, 5th International Thermal and Fluids Engineering Conference, April 5-8, 2020 (now postponed to 2021), New Orleans, LA.