Among our nation’s most powerful strategies for tackling climate change are electrifying transportation and accelerating clean power generation. Both these strategies have one essential thing in common: their success depends on advancements in battery technologies. Economical and fast-charging batteries are key to spurring adoption of all-electric and plugin-hybrid vehicles, while high-energy-density battery storage is needed to address the intermittency of solar and wind power and make the grid more responsive.

At EERE, our research and development investments throughout the past decade have yielded breakthroughs in battery cost and performance, while driving down weight and enhancing manufacturability. Now, in collaboration with other DOE Offices as well as other federal agencies, we are building on this track record to inspire new advances in batteries and further the journey toward a clean energy future. Today, on National Battery Day, I want to highlight the innovative and impactful work under way at EERE to topple technology barriers and speed market transformation.

EERE and Partners Leading the Charge

EERE is committed to ensuring that advances in battery technologies benefit everyone. To accomplish this, efforts are underway to reduce the cost, volume, and weight of batteries, while simultaneously improving the batteries' performance (power, energy, and durability) and ability to tolerate abuse conditions. Accomplishing these goals will require a series of strategies and initiatives, working with partners who share the vision of what batteries are capable of.

One key effort is the Federal Consortium for Advanced Batteries (FCAB), which provides a framework for cooperation and coordination among federal agencies having a stake in developing advanced battery technology and establishing a domestic supply of lithium batteries. In addition to DOE, FCAB includes the Departments of Commerce, Defense, and State. Each agency contributes its strengths towards a shared commitment to utilizing advanced batteries as a means of combatting climate change.

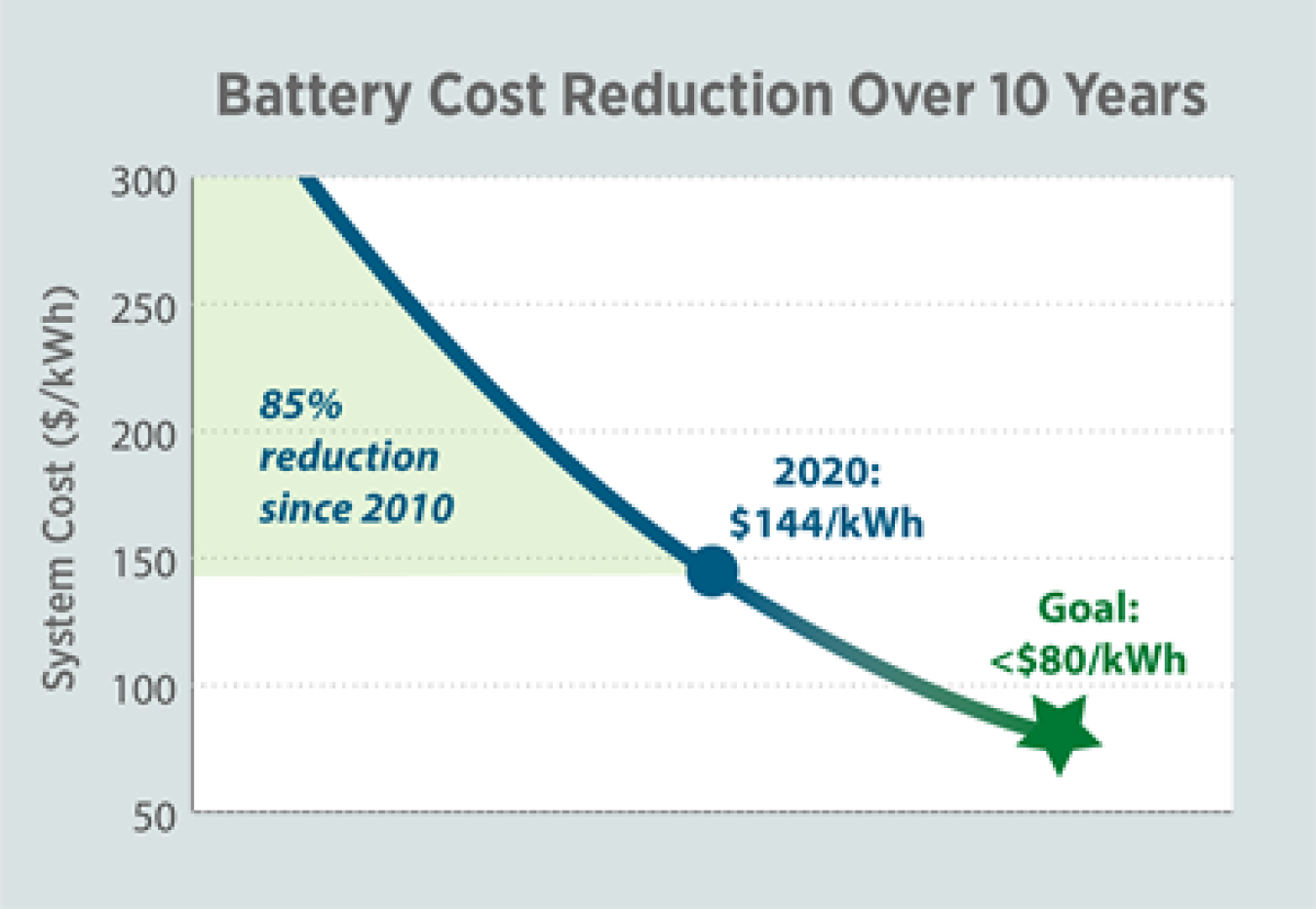

Over the past 10 years, DOE’s commitment to battery R&D has helped reduce the cost of lithium-ion batteries by ~85%.[1]

Within DOE, EERE is co-chair of the Energy Storage Grand Challenge (ESCG), a comprehensive program to accelerate the development, commercialization, and utilization of next-generation energy storage technologies. Launched in 2020, the ESGC is also co-chaired by the Office of Electricity, and includes the Office of Science, Office of Fossil Energy, Office of Nuclear Energy, Office of Technology Transitions, ARPA-E, Office of Policy, the Loan Programs Office, and the Office of the Chief Financial Officer. Recently, the ESGC released the ESGC Roadmap, which set the goal of developing and domestically manufacturing energy storage technologies that can meet all U.S. market demands by 2030. The Roadmap set aggressive cost targets representing a 44 percent reduction from current battery costs, laying the foundation for more cost-competitive electric vehicles and potentially benefitting the production, performance, and safety of batteries for stationary applications.

Battery Recycling and Critical Materials

Critical materials -- including rare earth elements with unique magnetic, catalytic, and luminescent properties -- are key resources needed to manufacture products for the clean energy economy, including wind turbines, solar panels, electric vehicles, and energy-efficient lighting. However, supply chain disruptions and price fluctuations associated with these valuable resources introduce uncertainty and instability in the production of these essential technologies. In the case of lithium-ion batteries, for example, reliable supplies of lithium and cobalt are vital to the manufacturing of products used for electric vehicles and grid energy storage.

DOE employs diverse strategies to address critical materials challenges. One important initiative is ReCell, the nation’s first lithium-ion battery recycling R&D center, launched by EERE’s Vehicle Technologies Office and based at Argonne National Laboratory. In the future, up to 40% of critical materials in batteries may be supplied from recycled batteries, making it one of the most important battery technologies the U.S. needs to develop. ReCell seeks to accelerate the growth of a profitable recycling market for spent electric vehicle, electronics, and stationary storage batteries by developing novel technologies. These technologies would use less energy-intensive processing methods and capture more valuable forms of materials for direct reuse in batteries. Through ReCell, researchers from industry, academia, and national laboratories will test new recycling techniques. The most promising processes will then be demonstrated at pilot scale, and validated processes will be available for license to industry.

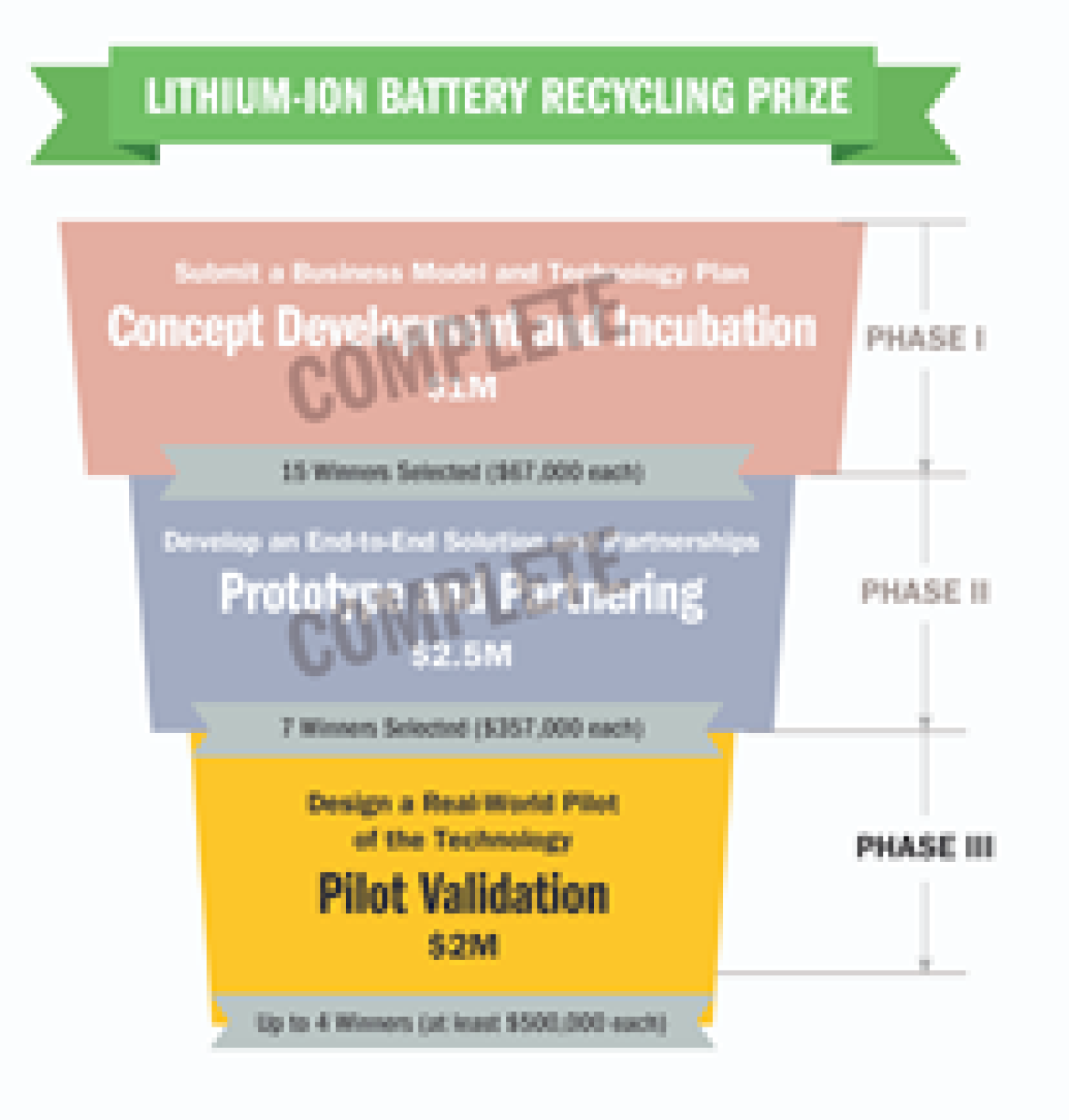

The Battery Recycling Prize recently launched Phase III, where the seven remaining teams will partner with industry experts and DOE’s National Laboratories to support their pilot validation.

In addition, DOE uses a prize competition to drive innovation in battery recycling. The Lithium-Ion Battery Recycling Prize, administered by the National Renewable Energy Laboratory, is designed to inspire solutions to collecting, storing, and transporting discarded lithium-ion batteries for eventual recycling. The goal is to develop and demonstrate processes that, when scaled, have the potential to profitably capture 90 percent of all discarded or spent lithium-based batteries in the United States and to re-introduce key materials into the U.S. supply chain. The innovative concepts being developed by the prize winners will give batteries a second life and recover resources to reuse time and time again.

Another strategy is the Critical Materials Institute (CMI), founded by DOE and led by Ames National Laboratory. CMI focuses sustained multidisciplinary R&D efforts on such issues as diversifying the supply of critical materials, developing substitute materials with lower or zero critical materials content, and improving reuse and recycling of critical materials. It also conducts crosscutting research to support enabling basic science needs, address environmental sustainability issues, and evaluate the social and economic viability of CMI-developed science and engineering solutions.

Pushing the Frontiers

At EERE, we leverage science and research to power President Biden’s climate and energy agenda. Our diverse strategies to advance energy storage technologies illustrate how creativity, coupled with a sense of urgency, can drive the market transformation and deployment needed to tackle climate change and sustain a clean energy economy. We can be proud of the scientific foundation for change that we have put in place.

That is why I wish all of you … a Happy National Battery Day!

1 https://www.anl.gov/cse/batpac-model-software