Abengoa’s biorefinery in Hugoton, Kansas, is the third cellulosic ethanol facility co-funded by the U.S. Department of Energy (DOE) to begin production at commercial scale since July 2013. The Department provides cost-shared funding to these first-of-a-kind facilities to help drive down technical risk and foster private investment in the growing U.S. bioeconomy.

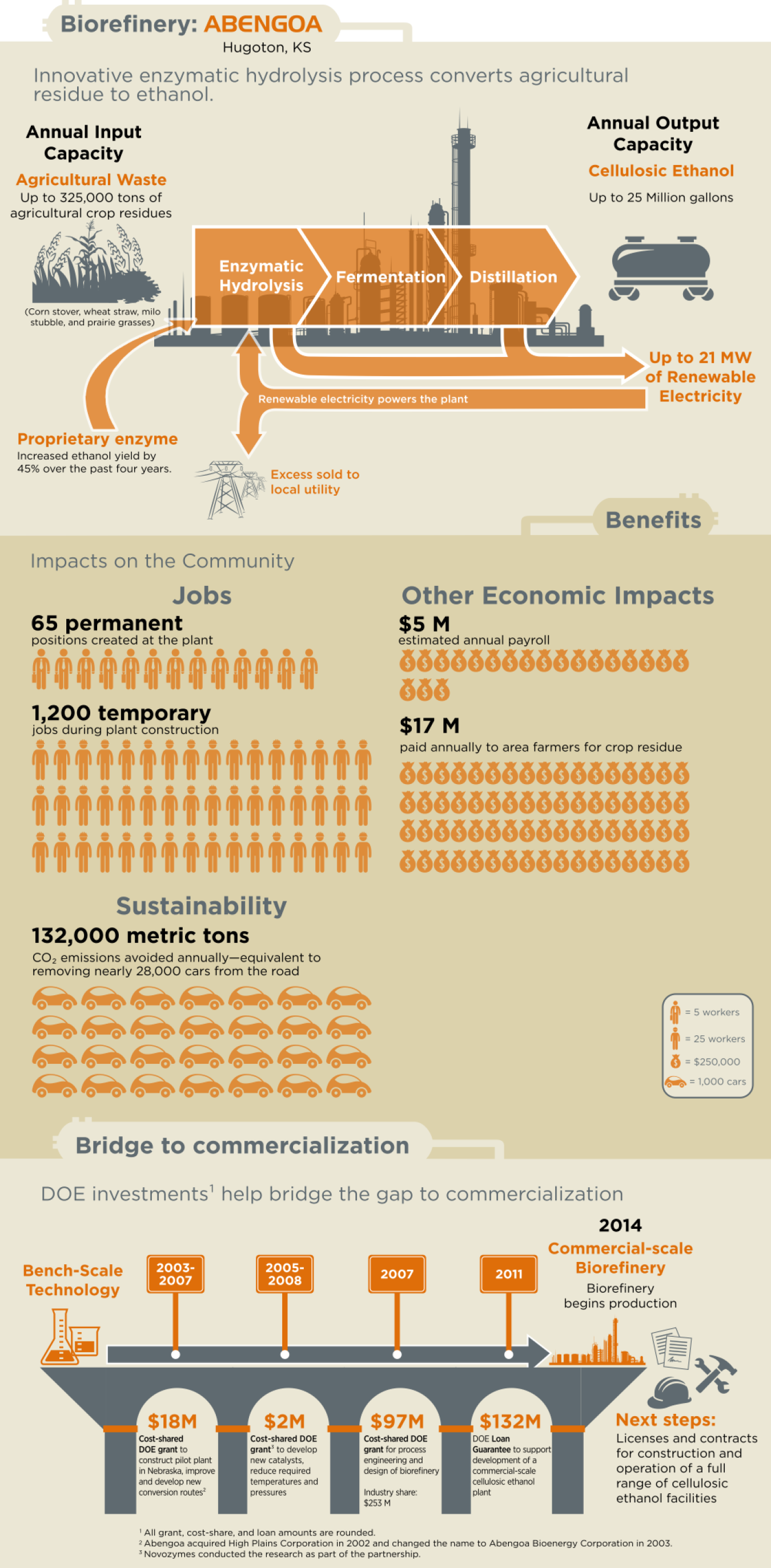

Abengoa designed and built the Kansas facility around an enzymatic hydrolysis process that was evaluated for more than 30,000 hours at pilot scale and for more than 6,000 hours at the demonstration scale. This innovative process converts a range of agricultural residues into sugars, which are then fermented, distilled, and dehydrated into denatured fuel ethanol for shipping to distribution centers in the region. The agricultural residues, which include corn stover, wheat straw, and seasonal grasses, span two or more growing seasons—helping to assure a reliable supply.

The Abengoa biorefinery has the capacity to convert up to 325,000 dry tons of agricultural residues into 25 million gallons of cellulosic ethanol each year. In addition, the facility’s integrated, biomass cogeneration plant will use the residual solids and waste water treatment biogas to generate up to 21 MW gross electrical power—enough to supply all of the biorefinery’s electricity needs and have a surplus for upload to the local grid. Steam extracted from the cogeneration system turbine also satisfies all steam requirements at the facility. Ash from the boiler system may be used for road construction or landscaping.

DOE awarded $97 million in cost-shared funding and a $132.4 million loan guarantee to facilitate the design, development, and construction of this landmark project. Like the INEOS biorefinery in Florida and the POET-DSM biorefinery in Iowa, Abengoa’s Hugoton facility is generating jobs, improving energy security, and reducing the greenhouse gases emitted over the lifecycle of this alternative fuel (relative to petroleum-based gasoline). For information on the other biorefineries that received cost-shared DOE support, visit Integrated Biorefineries. For information on DOE loan opportunities, visit Renewable Energy & Efficient Energy Projects Solicitation.