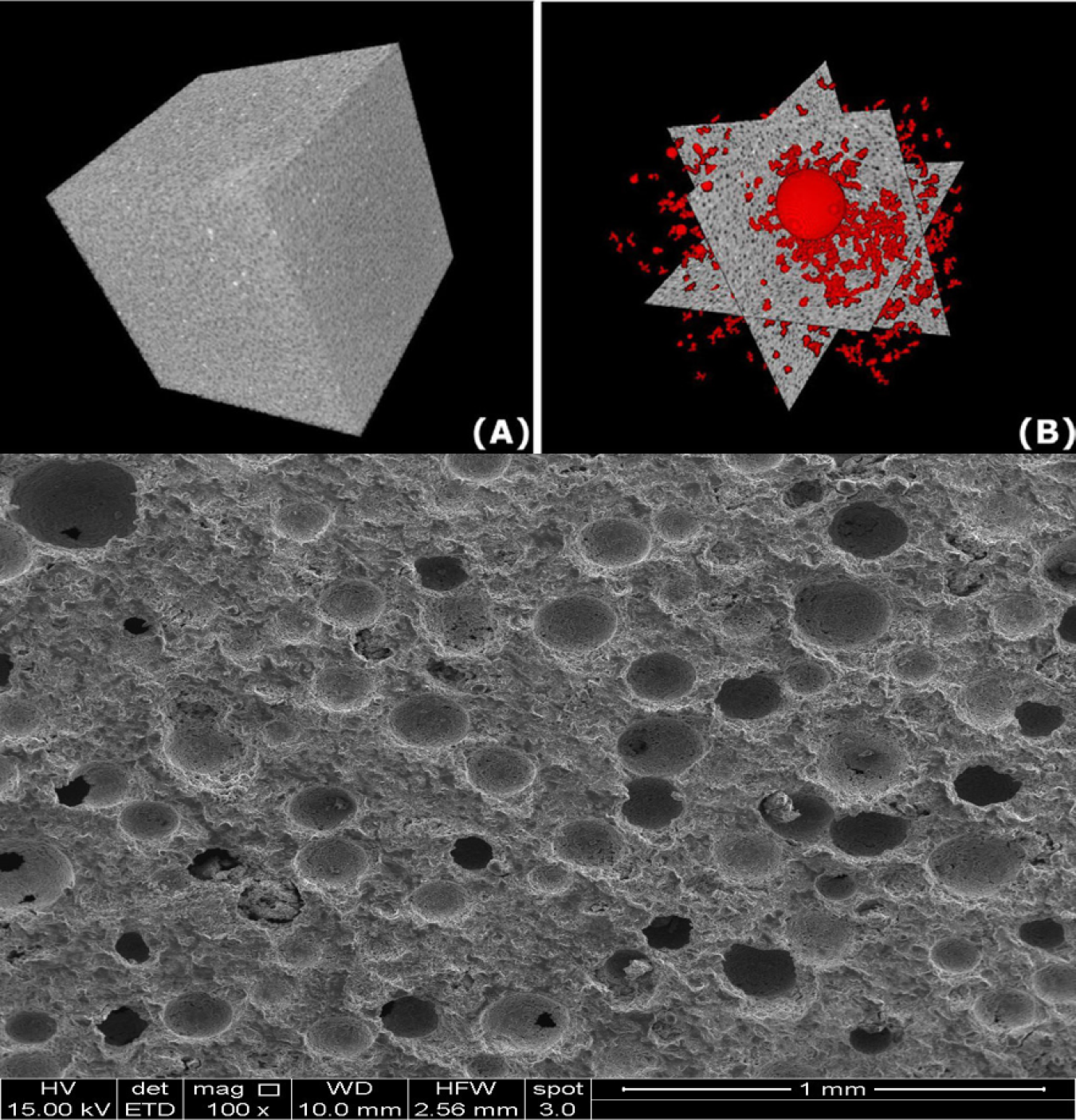

3-D renderings (A and B) and scanning electron image of foamed cement.

The Energy Department’s National Energy Technology Laboratory (NETL) is playing a key role in updating a 25-year-old testing standard that helps ensure quality, reduce cost, decrease waste, and support safer oil and gas operations around the world.

The research into foamed cement, which was featured in an Offshore magazine story titled “Research advances foamed cement applications,” was conducted by NETL scientists using the laboratory’s CT scanning equipment and subsurface geomechanics facilities. The work is part of the laboratory’s collaboration with the American Petroleum Institute’s (API’s) Subcommittee on Well Cements and Foamed Cement Work Group. The subcommittee is focused on closing the knowledge gap on foamed cement for uses in oil and gas wells.

Safe and environmentally sustainable oil and gas operations require complete isolation between the wellbore and the surrounding formation. So sealing the gap between the rock face and a well’s outer casing is critical. But unstable foams can result in unprotected sections within the well. That’s where foamed cement comes in.

Foamed cement is created when gases like nitrogen are injected into cement slurry to form microscopic bubbles. Foamed cement can be unstable if those bubbles become interconnecting, thereby causing gas leakage through the cement. On the other hand, stable foamed cement has a consistent density and a uniform distribution of bubbles throughout the well’s column, resulting in the strength and stability to protect against leaks and spills for the life of the well. Those characteristics makes it perfect for filling the gap in formations that are unable to support conventional cement slurries, such as those commonly found in the Gulf of Mexico.

NETL’s research shows that laboratory samples do not match foam cement generated in the field, resulting in inconsistent assessments of cement capabilities. The research also showed that the equipment used to generate foamed cement can have a major impact on the properties of the cement. These findings will help API update the 25-year-old foamed cement testing standard.

In addition to updating its testing standard based on NETL’s research, API is also preparing a technical report focused on foamed cement technology—one of only six published API technical reports in the history of the cement subcommittee. Meanwhile, oil and gas companies are using NETL’s research results to update their computer models and help make offshore oil and gas development safer and more sustainable.

Click here to learn more about NETL’s oil and gas research.