Lead Performer: Lawrence Berkeley National Laboratory (LBNL) – Berkeley, CA

Partners:

-- Attachments Energy Rating Council

-- Oak Ridge National Laboratory

-- Pacific Northwest National Laboratory

DOE Total Funding: $5,826,000 FY19+FY20. $2,700,000 estimated FY21

FY20 DOE Funding: $2,689,000

Cost Share: $409,000 (window wall panel project), $250,000? (Hi-R) - estimates

Project Term: October 1, 2018 - September 30, 2021

Funding Type: Direct Lab Funding

Project Objective

LBNL develops and maintains the enabling capabilities and facilities needed by the U.S. fenestration and fenestration attachment industry to develop and evaluate the energy performance attributes of emerging energy-efficient technologies. Main core capabilities and activities are highlighted below.

Window Attachments

Window attachments (e.g., shades, blinds) can have a significant impact on energy consumption in buildings.

- AERC: The Attachments Energy Rating Council (AERC) is a nonprofit, public interest organization aimed at providing reliable and credible information about window attachment performance. LBNL actively supported the establishment and operational start of AERC. LBNL technical expertise, software tools and measurement facilities continue to provide critical support to AERC’s activities.

- Window attachment analysis verification and testing: LBNL is leading, in partnership with ORNL and PNNL, this activity that builds on AERC’s program to further develop the rating system for window attachments, including the extension to commercial building products.

High-R, highly insulated windows reduce heat loss and gains, outdoor air infiltration, and mold and mildew caused by condensation. Thermal comfort near windows is improved, HVAC system can be downsized and perimeter zone heating can be eliminated in some climates.

- Thin triple glazing: Triple glazing with a nonstructural, thinner center layer allows triple glazing products to fit existing window cross-sections (drop-in replacement for double glazing), achieving higher insulation levels without the need for revised framing systems.

- Vacuum Insulated Glazing (VIG): VIG is a promising technology capable of meeting the rigorous thermal performance requirements of net-zero energy windows.

- Highly insulating commercial frames: Framing in commercial windows is primarily made of aluminum alloys, and even with the introduction of thermal breaks, it is still a weak component in a building facade. New thermal break technology and process helps substantially improve overall thermal performance and improve thermal comfort.

Daylighting and Facades

New fenestration technologies and systems that optimize the synergies between the façade, lighting, and mechanical systems can deliver high performance throughout a building’s lifespan. These "integrated" solutions represent a key opportunity to significantly reduce energy and demand.

- Model predictive controls (MPC): MPC can yield significant reductions in energy use and peak demand, enable greater responsiveness and stability of the utility grid as alternative renewable energy sources come on line, and improve occupant comfort and the indoor environmental quality of buildings.

Measurement Facilities

LBNL has facilities for measurement of window elements on scales ranging from full test beds for annual testing to lab instruments for analysis of the thermal and optical properties of individual elements of the products being studied.

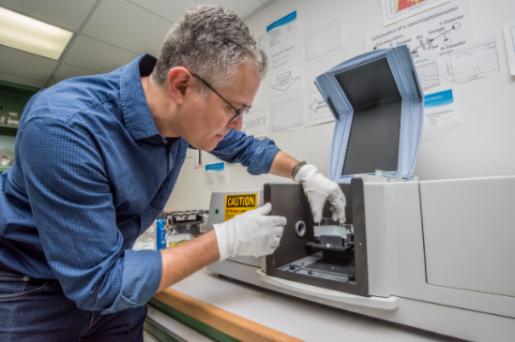

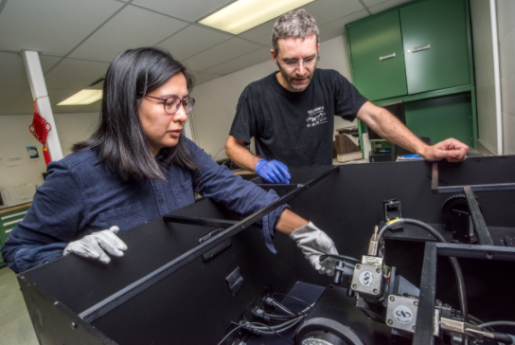

- Solar Optical Properties Laboratory: Measurement facility for transmittance and reflectance in the solar wavelength range, goniophotometers for angle-resolved scattering and thermal IR reflectance of low emissivity materials

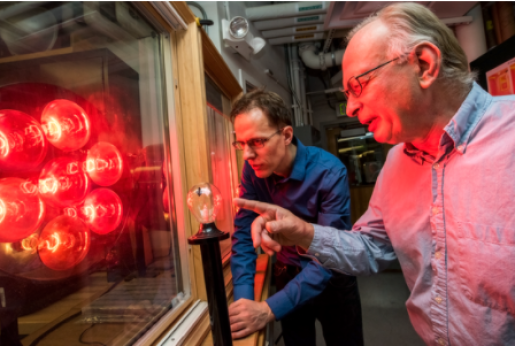

- Windows thermal testing facilities: Thermal testing facilities at LBNL serve to assure credibility of models and software tools and to determine thermal performance of new window products and technologies.

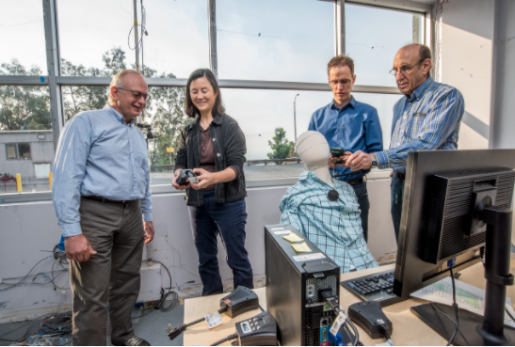

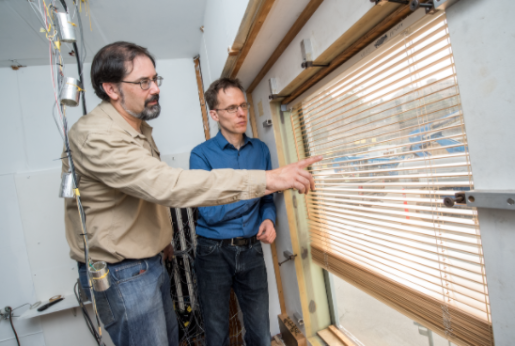

- Advanced Windows Testbed Facility: Full-scale system-level interactions between innovative façade systems and lighting and HVAC systems.

Software

Window software tools developed by LBNL over more than three decades have been key to the development, design and implementation of energy-efficient facade and window technologies.

- AERCalc: AERCalc is used to calculate the annual energy performance of window attachments.

- WINDOW: A computer program for calculating total window thermal performance indices.

- THERM: THERM's two-dimensional conduction heat-transfer analysis is based on the finite-element method, which can model the complicated geometries of building products.

- Radiance: A suite of programs for the analysis and visualization of lighting in design. It employs advanced Monte Carlo ray-tracing with optimizations for complex building geometries and fenestration systems.

- COMFEN: An interface that supports the systematic evaluation of alternative fenestration systems for project-specific commercial building applications.

- RESFEN: Evaluation of alternative fenestration systems for residential building applications.

- Optics: Tool for manipulating optical layers and calculating spectral data for different stacks of optical window components.

LBNL develops and maintains educational materials on windows research and development, with emphasis on helping researchers from a variety of other fields (e.g., material science, optics, controls) contribute to advances in the energy efficiency and comfort of windows.

Project Impact

Windows, as a major element of the building envelope, are an important factor in the overall energy use of buildings. Heat transfer through windows accounts for 4 quads of primary energy use in the U.S. today. Further, peak electric loads for cooling are dramatically increased in the summer months due to solar heat gain through windows. The long-term objective of this work is to facilitate transformation of the installed base of windows in the U.S. toward high-performance windows that can reduce overall energy use and consumers’ energy costs, increase summer and winter occupant comfort, and reduce peak demand driven by cooling systems.

Contacts

DOE Technology Manager: Marc LaFrance

Lead Performer: Dr. Charlie Curcija, Lawrence Berkeley National Laboratory