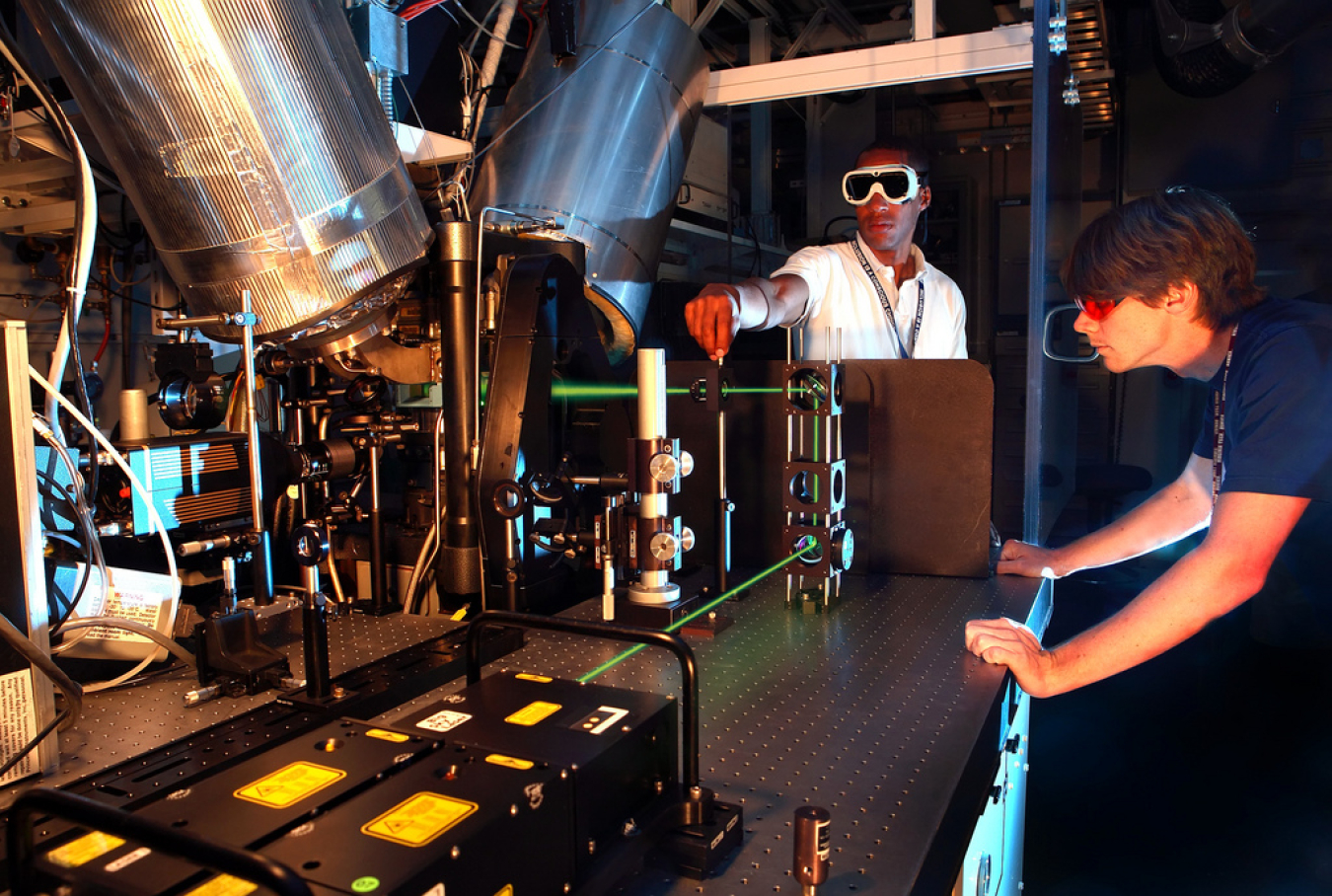

Researchers take laser-based velocity measurements at the Sandia National Laboratory's Combustion Research Facility. The measurements are used to help understand the flow features involved in the creation of in-cylinder carbon monoxide distributions in order to improve automotive diesel engines. | Photo by Randy Wong, Sandia National Laboratory

The Bioenergy Technologies Office is studying ways to economically process, transport and formulate raw biomass to develop new, more sustainable advanced biofuels that can take advantage of advanced engines’ new characteristics. | Idaho National Laboratory

Recently I had the pleasure of briefing members of Congress on EERE’s groundbreaking fuel-engine co-optimization initiative. The new, multi-year project combines previously independent areas of biofuels and engine combustion research and development (R&D) to design new fuels and engines that are co-optimized—designed in tandem to both maximize vehicle performance and carbon efficiency. Internal combustion engines will continue to play a role in our transportation mix for decades. Fuel and engine advancements in recent years have made vehicles cleaner and more fuel efficient, but there is a continued need to reduce the energy they require and the greenhouse gases they emit. For years, the Energy Department has been a leader in researching and developing breakthrough technologies to address energy and emissions issues, and this new initiative is yet another of our solutions to advance clean, energy-efficient technologies.

The fuel-engine co-optimization initiative fits perfectly into the Energy Department’s larger portfolio of sustainable transportation technologies. This project brings together EERE’s Vehicle Technologies Office, Bioenergy Technologies Office, and nine national laboratories, as well as numerous industry, government, and academic partners to help more rapidly identify commercially viable solutions.

On the vehicles front, EERE’s Vehicle Technologies Office and the national laboratories are building off existing research on advanced combustion engines to substantially improve engine efficiency and reduce greenhouse gas emissions. Initial laboratory engine test results indicate that for passenger vehicles, fuel economy improvements of more than 50% are possible. Maximizing vehicle performance and improving fuel efficiency saves consumers money on gasoline. Advanced combustion technologies can also limit the production of pollutants inside the engine that produce smog, minimizing the need for emissions reductions equipment that can reduce vehicle efficiency.

However, these new engine technologies are particularly sensitive to variations in fuel composition; therefore, the other half of the fuel-engine co-optimization initiative is to develop new, more sustainable advanced biofuels or other low greenhouse gas fuels that can take advantage of advanced engines’ new characteristics. For example, biofuels can have desirable components such as high octane or cetane that conventional engines cannot take full advantage of, but that would be well-suited to enable greater fuel economy in advanced engines and reduce life-cycle greenhouse gas emissions. The Bioenergy Technologies Office and national laboratories are working to provide a technical assessment of biofuel options that enable advanced engines, including an understanding of the fuels’ characteristics and combustion performance.

Throughout the project, analysts are evaluating proposed solutions from environmental and economic perspectives, in addition to examining market viability of the new engines and fuels. The project aims to improve fuel economy 15%–20% beyond the projected results of existing R&D efforts and to dramatically decrease transportation sector criteria pollutants and greenhouse emissions.

Co-optimized fuel-engine systems will reduce petroleum consumption, greenhouse gas emissions and pollutants from transportation while stimulating the economy and promoting US technology leadership.